- Joined

- Feb 20, 2019

- Messages

- 335

According to Borden's drawing above, if you have one of the actions listed with a magnum bolt face and no recoil lug.

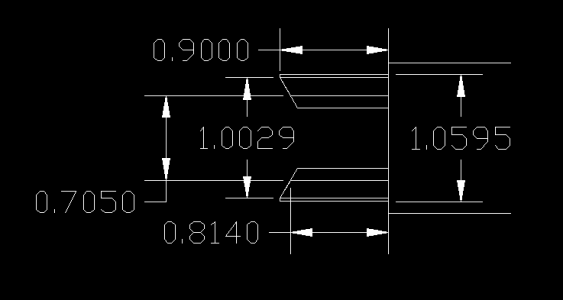

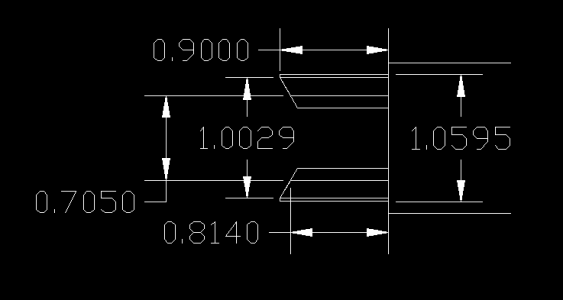

Again, you want to make sure your compound has enough movement to completely cut the cone. Then using the cutter your going to cut cone with (I use a carbide boring bar) you need to zero Y at your shoulder and set the measured dimension of tenon in X. If you move to 0.9 in Y, over to 1.003" in X and lock down carriage and use the compound, that should match their drawing. Now realize, you can't start at 1.003" and start cutting. You'll actually start closer to either bored hole or chamber wall. Then you'll be working X back to 1.003". When you get to 0.705" X in diameter mode, your Y should be 0.814". Now here is the unknown, I don't know what bolt nose clearance that leaves you with. The drawing doesn't have that. But since that last drawing above is guide for a CNC machine, I ASSUME that puts it mid-spec (.005"-.010"). I'd do a test tenon and verify dimensions match old barrel using same tools to measure both.

Again, you want to make sure your compound has enough movement to completely cut the cone. Then using the cutter your going to cut cone with (I use a carbide boring bar) you need to zero Y at your shoulder and set the measured dimension of tenon in X. If you move to 0.9 in Y, over to 1.003" in X and lock down carriage and use the compound, that should match their drawing. Now realize, you can't start at 1.003" and start cutting. You'll actually start closer to either bored hole or chamber wall. Then you'll be working X back to 1.003". When you get to 0.705" X in diameter mode, your Y should be 0.814". Now here is the unknown, I don't know what bolt nose clearance that leaves you with. The drawing doesn't have that. But since that last drawing above is guide for a CNC machine, I ASSUME that puts it mid-spec (.005"-.010"). I'd do a test tenon and verify dimensions match old barrel using same tools to measure both.

Last edited: