-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HELP! G0602 Problem

- Thread starter sepulling

- Start date

I've seen split nuts, but I haven't seen one exactly like that. Are you sure it's broke? I'm looking at the pic trying to figure out how it works. Does the set screw push the piece down to kind of bind the threads and tighten the motion? If you had the nut fastened in place and the piece inserted with the set screw holding it, could you start the screw and then tighten the set screw after you had the cross feed screw through the nut? If it wasn't in two separate pieces I don't see how it could work.

Chuck

Chuck

- Joined

- Apr 1, 2013

- Messages

- 1,142

If I recall right from mine the pointed set screw spreads the two halves of the split nut to take up slack on the screw. it was eiter over tight or or faulty, or shock loaded.

I've seen split nuts, but I haven't seen one exactly like that. Are you sure it's broke? I'm looking at the pic trying to figure out how it works. Does the set screw push the piece down to kind of bind the threads and tighten the motion? If you had the nut fastened in place and the piece inserted with the set screw holding it, could you start the screw and then tighten the set screw after you had the cross feed screw through the nut? If it wasn't in two separate pieces I don't see how it could work.

Chuck

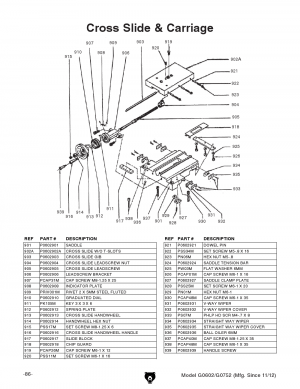

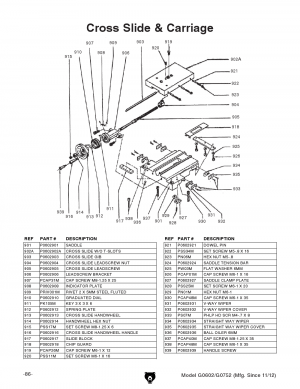

Yeah it's definitely broken, that would actually be a side view of how it goes in, the smaller piece is what was broken, it almost looks like the set screw is supposed to wedge in the gap and like you said allow it to tighten up on the threads of the screw. The socket head cap screw is actually what they describe in the the manual as the adjustment screw and the set screw isnt even mentioned. Like I said the manual is horrible lol. Here is an exploded view..... I ordered a new one but still dont know how its supposed to be adjusted correctly

- Joined

- Apr 1, 2013

- Messages

- 1,142

well you don't want it so tight than it feels in a bind. it should have a few thous of lash but not more than 5

Yeah it's definitely broken, that would actually be a side view of how it goes in, the smaller piece is what was broken, it almost looks like the set screw is supposed to wedge in the gap and like you said allow it to tighten up on the threads of the screw. The socket head cap screw is actually what they describe in the the manual as the adjustment screw and the set screw isnt even mentioned. Like I said the manual is horrible lol. Here is an exploded view..... I ordered a new one but still dont know how its supposed to be adjusted correctly

Last edited:

Yeah it's definitely broken, that would actually be a side view of how it goes in, the smaller piece is what was broken, it almost looks like the set screw is supposed to wedge in the gap and like you said allow it to tighten up on the threads of the screw. The socket head cap screw is actually what they describe in the the manual as the adjustment screw and the set screw isnt even mentioned. Like I said the manual is horrible lol. Here is an exploded view..... I ordered a new one but still dont know how its supposed to be adjusted correctly

The Grizzly manual for the G0602 lathe has the adjustment procedure on page 60.