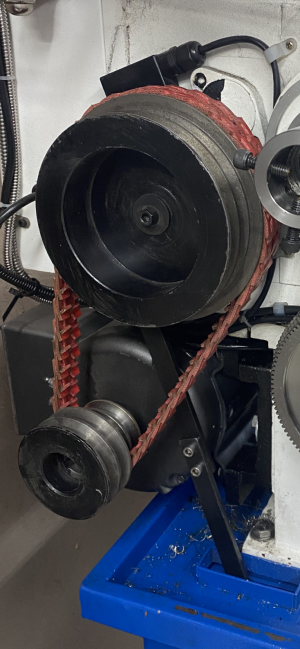

Actually i was moving the change gears to do some 18 TPI threads and went down a rabbit hole. I was hearing what sounded like bearing noise and the only way to tell was to remove the motor so i could listen to the bearings. It took and hour and a half to remove the motor due to poor design. I even had to get my wife to come out at 6:00 PM last night to help remove a bolt i couldn't get to with my Herman Munster hands.

So i came here to the search and found several threads like you mentioned. I thought i may as well isolate the motor while i am at it. Three phase isnt in the budget this time around.

I also have the motor pulley hanging out to the end of the shaft, etc.

Thanks, Joe

![IMG_0712[3].jpg](/data/attachments/438/438352-8d8aa13d00250f1786873c9ee19bef3f.jpg)