- Joined

- Dec 18, 2013

- Messages

- 2,012

I made some more improvements to my G4003G lathe by fixing some quality issues and installed some thick rubber washers to dampen vibration from the motor. Lets start with the quality issues...

Notice how far the pulley sticks out on the shaft, pretty lame.

Here's another pic, unacceptable imo PLUS the pulley was bored so poorly it wobbled a like it was made of jello. Luckily the replacement pulley arrived from Grizzly today 2 weeks earlier than expected! Replacement pulley was straight and true.

Here's why the pulley was sticking out so far on the shaft, the factory drilled the mounting holes too far to the left so the only way they could align the motor pulley to the spindle pulley was to hang it out off the end of the motor shaft (facepalm) Also note how they snaked the two cables through this mount e.g. between the motor and the motor mount, I re-routed one of these above and the other to the left of the motor, this allowed me to bolt the motor onto this motor mount while on the work bench WAY easier.

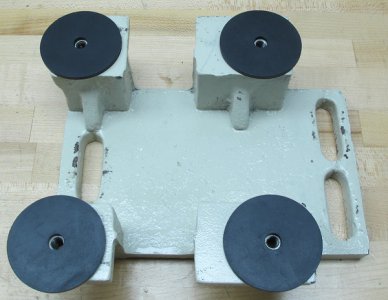

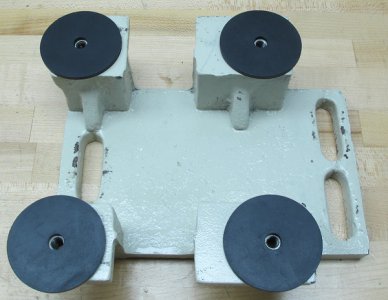

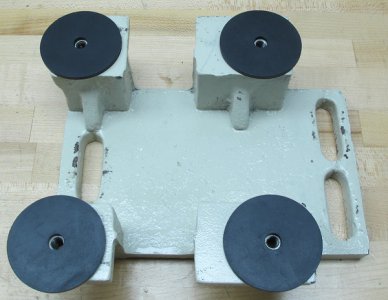

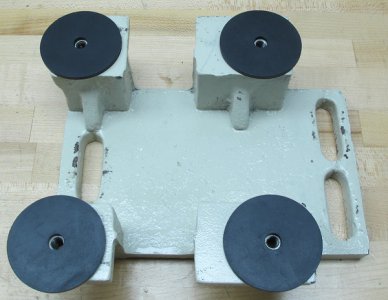

Here I have re-drilled and tapped the motor mount holes 5/16-18 relocating the holes about .400 inches towards the headstock. I also picked up some large 1/8 inch thick rubber washers at my local hardware store to dampen any vibration from the motor, I added smaller 5/16 rubber washers between the mounting bolts and motor, I used some grade 8 bolts I hand on hand. I have read where a few guys have isolated the motor from the lathe with rubber and this improved finish, meh I figured it couldn't hurt while I had everything apart. Also for the three large bolts that bolt this mount to the lathe, the CHINA washers were not so great, one was already bent inwards into the slot from the factory. I picked up some grade 8 thick washers to replace them.

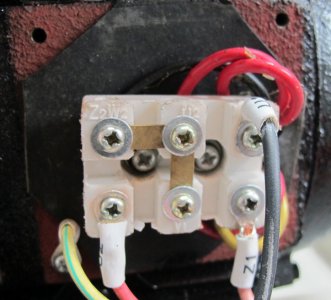

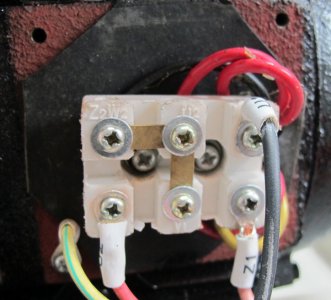

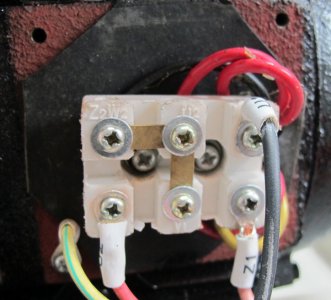

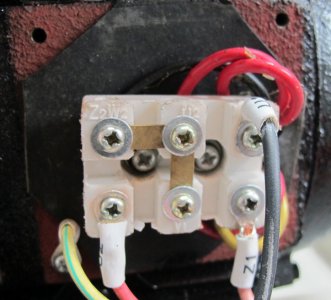

This was the next quality issue, I had to unwire the motor to remove it, see the red wire lower left its missing a washer. I wondered why this wire was loose during disassembly, I found out later without the washer the screw bottoms out in the hole leaving the wire loose. I added a washer to fix this.

Here I'm using my digital angle gauge to align the motor parallel to the spindle pulley shaft, this tool makes it easy. I used a wood block and some wood shims to hold up/position the left side of the motor while I set the belt tension and tightened the right bolt. I also aligned the pulleys vertically.

Certainly closer than I could have eyeballed it. Notice how much farther onto the motor shaft the pulley is now, its nearly flush with the end of the shaft.

Buttoned everything up and celebrated with a cold beverage.

Notice how far the pulley sticks out on the shaft, pretty lame.

Here's another pic, unacceptable imo PLUS the pulley was bored so poorly it wobbled a like it was made of jello. Luckily the replacement pulley arrived from Grizzly today 2 weeks earlier than expected! Replacement pulley was straight and true.

Here's why the pulley was sticking out so far on the shaft, the factory drilled the mounting holes too far to the left so the only way they could align the motor pulley to the spindle pulley was to hang it out off the end of the motor shaft (facepalm) Also note how they snaked the two cables through this mount e.g. between the motor and the motor mount, I re-routed one of these above and the other to the left of the motor, this allowed me to bolt the motor onto this motor mount while on the work bench WAY easier.

Here I have re-drilled and tapped the motor mount holes 5/16-18 relocating the holes about .400 inches towards the headstock. I also picked up some large 1/8 inch thick rubber washers at my local hardware store to dampen any vibration from the motor, I added smaller 5/16 rubber washers between the mounting bolts and motor, I used some grade 8 bolts I hand on hand. I have read where a few guys have isolated the motor from the lathe with rubber and this improved finish, meh I figured it couldn't hurt while I had everything apart. Also for the three large bolts that bolt this mount to the lathe, the CHINA washers were not so great, one was already bent inwards into the slot from the factory. I picked up some grade 8 thick washers to replace them.

This was the next quality issue, I had to unwire the motor to remove it, see the red wire lower left its missing a washer. I wondered why this wire was loose during disassembly, I found out later without the washer the screw bottoms out in the hole leaving the wire loose. I added a washer to fix this.

Here I'm using my digital angle gauge to align the motor parallel to the spindle pulley shaft, this tool makes it easy. I used a wood block and some wood shims to hold up/position the left side of the motor while I set the belt tension and tightened the right bolt. I also aligned the pulleys vertically.

Certainly closer than I could have eyeballed it. Notice how much farther onto the motor shaft the pulley is now, its nearly flush with the end of the shaft.

Buttoned everything up and celebrated with a cold beverage.