- Joined

- Nov 22, 2022

- Messages

- 358

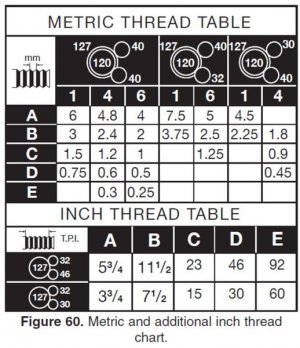

The 2 small gears are going to be 40 tooth, I don't remember the tooth count on the larger gears on this lathe, But if the 2, 40 tooth gears are installed now, Then its set up for inch threads. The metric ones If I remember correctly are 30, 32 and 46The internet has everything you will need. Just enter Grizzly DF1237G, the manuals and info is all there, you can find it.