- Joined

- Dec 18, 2013

- Messages

- 2,012

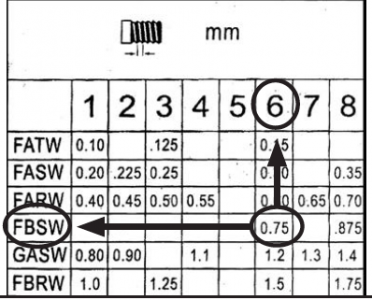

I noticed that there are basically four gear arrangements noted on the front of the lathe and in the manual (which can't seem to answer my question...).

Can I 'assume' that the four gearing arrangements are for inch, metric, module and diametral threading? I am looking for a lathe that I do not have to change gears to switch back and forth between inch feeds and threading and this one appears to do just that.

And now that you've had this for a while, have you had any issues with your lathe? I will admit that this lathe is right at my pain threshold for size and weight. I'm going to have to move my machines hopefully only one more time so I am keeping this in mind while I shop for my 'big lathe'.

Thanks for your thoughts.

Will Bill purchase the G4003G...(shakes the magic8 ball)...

Last edited by a moderator: