-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Rocketry Discussion!

- Thread starter Weldo

- Start date

- Joined

- Sep 7, 2019

- Messages

- 674

Yesterday I was cruising around the inter-screen looking for balsa blocks for sale and happened upon a shop called BalsaWoodShop.com. They had 2x4x12" blocks that I could laminate to make a nose cone.

Then I noticed that they are local to Pittsburgh! I gotta find some time to go check them out! The balsa shop is a web store front maintained by Bill and Walt's Hobby Shop, can't wait to visit!

I think I'm going to buy some shock cord too but everything else I'd like to make, even the motor mount tube.

I had good luck in the past by rolling heavy brown paper smeared with wood glue to make a small tube. Wrap it around a mandrel and wrap with Saran wrap, after it cures trim to length. I made a 1/2" ID square tube this way once and came out pretty darn rigid.

Then I noticed that they are local to Pittsburgh! I gotta find some time to go check them out! The balsa shop is a web store front maintained by Bill and Walt's Hobby Shop, can't wait to visit!

I think I'm going to buy some shock cord too but everything else I'd like to make, even the motor mount tube.

I had good luck in the past by rolling heavy brown paper smeared with wood glue to make a small tube. Wrap it around a mandrel and wrap with Saran wrap, after it cures trim to length. I made a 1/2" ID square tube this way once and came out pretty darn rigid.

- Joined

- Jan 10, 2019

- Messages

- 1,042

And for nearly all of our homemade rockets, we found that streamers worked much better than parachutes. The whole point is to slow it down just enough that it doesn't break when it lands, and no more. Any more is a waste and risks it floating away.

The program says 23.8 ft/s off a 36" rod.

I usually like to see about 30 ft/s. You are probably alright if you launch in low wind though. You could try moving to a longer rod if you are concerned.

- Joined

- Jan 2, 2014

- Messages

- 8,852

Any more is a waste and risks it floating away.

Yep, lost a few that way over the years......

-brino

- Joined

- Sep 7, 2019

- Messages

- 674

And for nearly all of our homemade rockets, we found that streamers worked much better than parachutes. The whole point is to slow it down just enough that it doesn't break when it lands, and no more. Any more is a waste and risks it floating away.

Thanks, streamers are a bit easier than parachutes to deal with. Do you think a streamer is adequate to slow down a 20 ounce rocket?

I usually like to see about 30 ft/s. You are probably alright if you launch in low wind though. You could try moving to a longer rod if you are concerned.

A longer rod is a good idea. Maybe a length of drill rod? Should be about as stiff as a 3/16" rod can be. Or maybe go up to 1/4"?

- Joined

- Sep 7, 2019

- Messages

- 674

I changed the simulation to a 48" launch rod and it yielded 25.4 ft/s off the rod.

Also it was a slow day at work so I had time to get to the hobby shop! They had all kinds of balsa blocks, some as big as 2x6x36"!

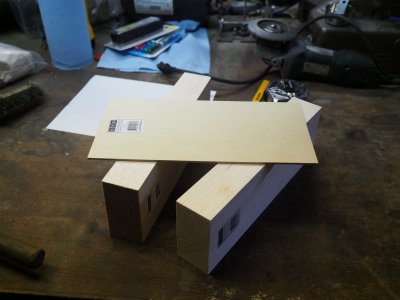

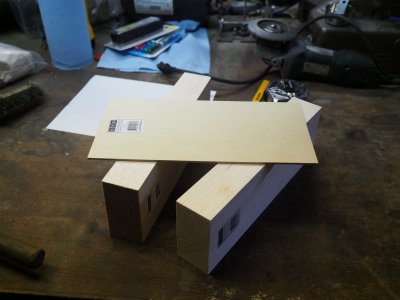

I picked up two 2x4x12" pieces and glued them together. Gonna see where it goes from there. I also got a small 1/8" plywood for rings and bulkheads.

I need the centering rings to be perfectly centered so how about drilling an appropriate center hole then mounting them on some kind of arbor for lathe turning to the proper OD? Any ideas for the process of making perfect centering rings?

Also it was a slow day at work so I had time to get to the hobby shop! They had all kinds of balsa blocks, some as big as 2x6x36"!

I picked up two 2x4x12" pieces and glued them together. Gonna see where it goes from there. I also got a small 1/8" plywood for rings and bulkheads.

I need the centering rings to be perfectly centered so how about drilling an appropriate center hole then mounting them on some kind of arbor for lathe turning to the proper OD? Any ideas for the process of making perfect centering rings?

I would use 1/4" for something this size. Or a rail if I didn't mind limiting myself to club launches as I haven't built a rail pad.

For rings, my favorite way was to use a dremel router setup and a nail for the center. A fly cutter on a drill press works as well. The lathe is a good option as well. These days, I use a CNC router, because I have one.

For rings, my favorite way was to use a dremel router setup and a nail for the center. A fly cutter on a drill press works as well. The lathe is a good option as well. These days, I use a CNC router, because I have one.

- Joined

- Sep 7, 2019

- Messages

- 674

These days, I use a CNC router, because I have one

Ha ha, did you ever think the day would come when regular guys could have CNC equipment in their basements?! What an age, really!

Honestly I've been intrigued by some of the new table top laser cutters. Would be great for a project like this! I've been lusting after one of these lately...

For rings, my favorite way was to use a dremel router setup and a nail for the center. A fly cutter on a drill press works as well. The lathe is a good option as well.

I'll look into that! Unbelievably, I have a router base for the dremel and a fly cutter! I'll do some experimentation.

I'll also check out a 1/4" rod. Not familiar with rail type launchers. How does that work? I guess it's sturdier than a rod upon lift off?

Rails are great, but kind of overkill for smaller rockets. They are made from 80/20 aluminum extrusion. The rocket has connectors on the side that fit in the slots of the rail. Much more rigid, particularly for high power stuff. Don't worry about it for now, but if you go much bigger or get a lot of rod whip, come back to it.

Yeah, it's awesome that CNC gear is affordable enough for normal people to get. I recently got laser too.. Lol... I went with a Chinese import. Significantly less expensive than glowforge, bigger and higher power as well. Also doesn't require internet to work. No support though, so you have to be willing to get your hands dirty. If you do get a laser, remember that you need ventilation to outside and water cooling.

Yeah, it's awesome that CNC gear is affordable enough for normal people to get. I recently got laser too.. Lol... I went with a Chinese import. Significantly less expensive than glowforge, bigger and higher power as well. Also doesn't require internet to work. No support though, so you have to be willing to get your hands dirty. If you do get a laser, remember that you need ventilation to outside and water cooling.