- Joined

- Sep 7, 2019

- Messages

- 674

Neat idea?! Sheez, back in the late 60s, we built our own almost exclusively

Haha, I guess I'm a bit spoiled with all the great kits on the market! I've been toying with the idea of doing a scratch build and I like the idea of the slow lift off.

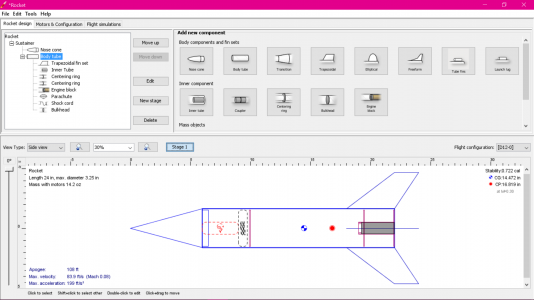

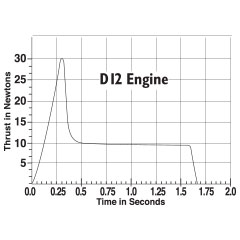

So an Estes D12-3 recommends a max (estimated) lift weight of 14oz. Anyone know if that's the actual weight at which a rocket will no longer leave the launch pad? If lift off is too slow I imagine the rocket will become unstable and dangerous, I don't want it to go up about 12 feet and spin around!

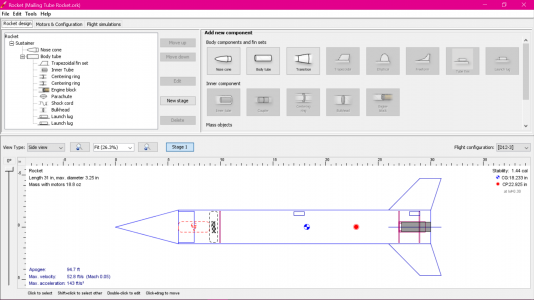

The tube I have is 3-1/4" OD, 3" ID and 37" long. Right now it's about 17.5oz so that's about 0.473oz per inch of tube.

If I cut it down to maybe 18" it'll be about 8.5oz, giving me some allowance for fins, a motor housing and nose cone. For fins I have some 0.080" plexiglass layin' around, it's pretty light and strong.

Nose cone could be built off the tube end caps, maybe glue on an old funnel or a plastic champagne glass?

Just thinking out loud here! Chime in if this sounds like a horrible idea!