- Joined

- Dec 6, 2012

- Messages

- 2,677

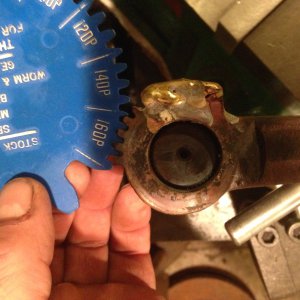

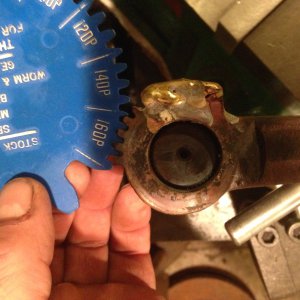

There were two gears stripped off inside the column of my Van Norman 22LU.

I found a used one Ebay at a price I was willing to pay.

The gear is cast brass.

The teeth were completely sheared off.

As you can see I've brazed over the broken teeth.

Without a complete gear how do I calculate the spacing for my DH?

As you can see by the gear gage she appears to be a 16tooth.

Suggestions?

Thank you!!

Daryl

MN

I found a used one Ebay at a price I was willing to pay.

The gear is cast brass.

The teeth were completely sheared off.

As you can see I've brazed over the broken teeth.

Without a complete gear how do I calculate the spacing for my DH?

As you can see by the gear gage she appears to be a 16tooth.

Suggestions?

Thank you!!

Daryl

MN