- Joined

- Apr 8, 2013

- Messages

- 1,980

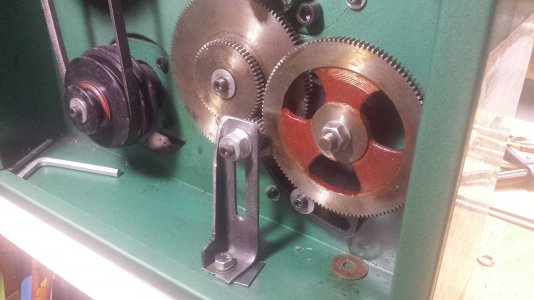

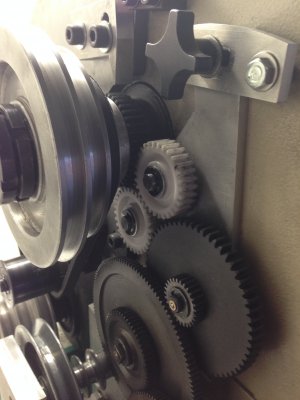

Oh, I see that now. A while back I saw a video of a guy that made a tumbler for (I think) a Grizzly lathe. He did it by accessing the first gear out of the headstock so it was up high and he could still change the gears below. It was pretty slick. I'll try to find it.But remember in #14 above I scraped that motor idea and went back to the idler gear as pictured above.