- Joined

- Feb 1, 2015

- Messages

- 9,605

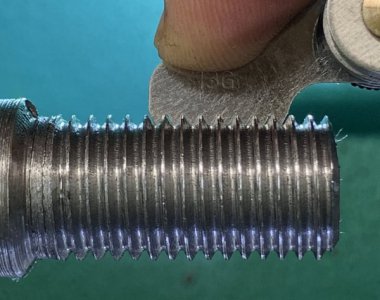

I have a 602 and the scale reads zero when the compound travel is parallel to the spindle axis. If you elect to use the compound to in-feed when cutting, you need to set the compound to 60.5º to achieve the 29.5º feed angle. Also, keep in mind that the divisions on the scale are actually 2.5º so you would set to just a bit past the 60º mark.

There have been a number of discussions on this forum about this same problem. Once you get it figured out, I think you will find threading with the 602 to be simple. Here is how I set mine up. https://www.hobby-machinist.com/threads/29-5-deg-angle-tool-for-lathe.34541/#post-299219

There have been a number of discussions on this forum about this same problem. Once you get it figured out, I think you will find threading with the 602 to be simple. Here is how I set mine up. https://www.hobby-machinist.com/threads/29-5-deg-angle-tool-for-lathe.34541/#post-299219