-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Found this on Craigslist. Can anyone tell me about it?

- Thread starter alloy

- Start date

Putting a plank or two under the trailer tires would lift it a little. Just eyeballing it though, I'm not sure you'd need to put the shop crane that far under the trailer. That lathe should weigh roughly 800 to 1000 lbs since my 36" Clausing has a weight of 1100 lbs. You could have the crane's boom fully extended without exceeding the lifting weight at that extension - 1/2 ton. Of course, I'm not there in person to see it, but it looks like you should be able to pull the lathe to the rear of the trailer and lift it with the shop crane without having to get under the axle. The sling will go closer to the head than the middle of the bed, and you use the tailstock and carriage to make it balance. Remember to put a board wider than the width of the bed plus the lead screw under it before lifting. If you lift under the bed alone without that board, you're likely to bend the lead screw. .

Roll it in your shop on thick wall pipe Egyptian style. Note that you might have to remove the cover at the rear of the headstock or tailstock if they can't support the load. I had to do that for mine, but your stand may be different. The photos were taken in Jan 2010 and the outdoor temp was 13º.

Roll it in your shop on thick wall pipe Egyptian style. Note that you might have to remove the cover at the rear of the headstock or tailstock if they can't support the load. I had to do that for mine, but your stand may be different. The photos were taken in Jan 2010 and the outdoor temp was 13º.

- Joined

- Jul 5, 2014

- Messages

- 2,782

Wow everyone is so helpful

I think I'm going to hook the trailer back up to my rig to stabilize it, then jack it up put some jack stands under the axle or blocks, what ever ends up working. When we put it in the trailer we had the sling as close to the chuck as possible to balance it out.

But like I said I'm fried tonight. I haven't been sick for over a year now, and in just one day I've got no voice at all and am sick as a dog. I can only manage a whisper right now. I need to get some hydraulic oil for the crane and I'll get it off the trailer tomorrow and take the trailer back and come inside and stay warm. I can research the lathe and have information when I'm feeling better.

I think I'm going to hook the trailer back up to my rig to stabilize it, then jack it up put some jack stands under the axle or blocks, what ever ends up working. When we put it in the trailer we had the sling as close to the chuck as possible to balance it out.

But like I said I'm fried tonight. I haven't been sick for over a year now, and in just one day I've got no voice at all and am sick as a dog. I can only manage a whisper right now. I need to get some hydraulic oil for the crane and I'll get it off the trailer tomorrow and take the trailer back and come inside and stay warm. I can research the lathe and have information when I'm feeling better.

- Joined

- Sep 28, 2013

- Messages

- 4,319

Woohoo! Congratulations, well done! I'm so pleased you finally found the lathe you wanted and at such a good price too. What a journey! Now you have the fun part of tooling her up and making chips. Oh, and get well soon

- Joined

- Sep 10, 2013

- Messages

- 562

Wow everyone is so helpful

I think I'm going to hook the trailer back up to my rig to stabilize it, then jack it up put some jack stands under the axle or blocks, what ever ends up working. When we put it in the trailer we had the sling as close to the chuck as possible to balance it out.

But like I said I'm fried tonight. I haven't been sick for over a year now, and in just one day I've got no voice at all and am sick as a dog. I can only manage a whisper right now. I need to get some hydraulic oil for the crane and I'll get it off the trailer tomorrow and take the trailer back and come inside and stay warm. I can research the lathe and have information when I'm feeling better.

Congrats on scoring the lathe. You got a smoking deal. You should have no problem getting a 1" bar through the spindle bore. Spec is 1 1/16" bore with a 1 3/8" nose opening. When you get better and feel like it make sure that straps do not put pressure on the lead screw when you lift. If the lead screw gets bent it will show up in your finish of your turnings. You will see a pater of the RPM and TPI of the lead screw. it don't do any favors to you single point threads either. Get well soon and happy machining.

CH

- Joined

- Jul 5, 2014

- Messages

- 2,782

I'll make sure I'm clear of the lead screw when I lift it.

I will be working on getting it unloaded a little later today. Running some errands this morning and need to get some hydraulic oil for my crane. Seems to have gotten a little low on fluid in the last several years since I've used it.

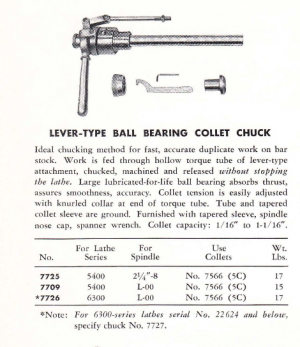

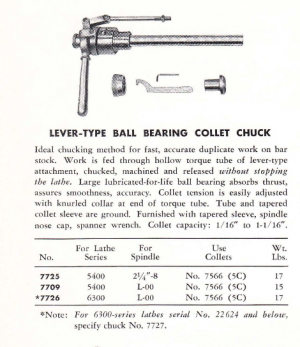

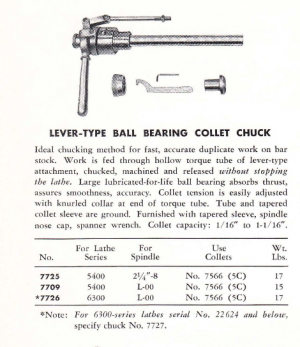

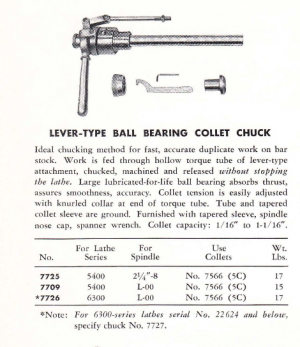

I have an old Royal collet closer from the 4 axis on my VMC that I had. I'd like to adapt it to the Lathe if possible. I'll be looking into that also.

I also need to figure out how to run this thing

I will be working on getting it unloaded a little later today. Running some errands this morning and need to get some hydraulic oil for my crane. Seems to have gotten a little low on fluid in the last several years since I've used it.

I have an old Royal collet closer from the 4 axis on my VMC that I had. I'd like to adapt it to the Lathe if possible. I'll be looking into that also.

I also need to figure out how to run this thing

- Joined

- Jul 5, 2014

- Messages

- 2,782

Got it unloaded with no problem. A couple of 2" x 12"s under the trailer tires did it.

In looking it over I see that the motor has been replaced with a 2 1/2 HP one. From what I can find out originally they came with either a 3/4 HP or an optional 1 HP motor. So with 2 1/2 times the original power I shouldn't have a lack of power problem. Looks like he cut the cabinet to fit the larger motor in.

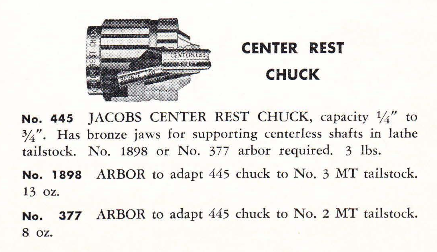

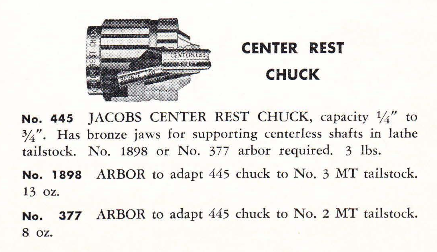

There is a lot of HS tooling with it. Some of it is brand new. The taper attachment looks like it's never been installed. I'm going to have to figure that one out. There is also a Jacobs keyless chuck. I've never seen one like it before.

Like I said before I have a Royal 5C collet closer and it fits perfectly through the spindle. The draw bar is way too short, but I'm thinking maybe I can us 5C collet stop extensions to lengthen the tube, or I'll just make my own.

Somethingelse to figure out is how to put a DRO on it. There isn't much room on the cross slide for the scale.

In looking it over I see that the motor has been replaced with a 2 1/2 HP one. From what I can find out originally they came with either a 3/4 HP or an optional 1 HP motor. So with 2 1/2 times the original power I shouldn't have a lack of power problem. Looks like he cut the cabinet to fit the larger motor in.

There is a lot of HS tooling with it. Some of it is brand new. The taper attachment looks like it's never been installed. I'm going to have to figure that one out. There is also a Jacobs keyless chuck. I've never seen one like it before.

Like I said before I have a Royal 5C collet closer and it fits perfectly through the spindle. The draw bar is way too short, but I'm thinking maybe I can us 5C collet stop extensions to lengthen the tube, or I'll just make my own.

Somethingelse to figure out is how to put a DRO on it. There isn't much room on the cross slide for the scale.

Last edited:

I see the former owner put the lathe on wheels. That's convenient, but it may affect accuracy. I looked at the snow pictures to see where it had snowed and noticed that you're in Vancouver, WA. I've been there a few times over the past 20 years or so to visit my sister. She and her husband just moved from Camas, WA just outside Vancouver to the Tacoma area this past year.

- Joined

- Jul 5, 2014

- Messages

- 2,782

Yes it was on wheels, I took them off to haul it, but put them back on for now to be able to move it around easily while working on it. When I'm ready to start using it I'll remove the wheels and level it up.

Looks like odd looking chuck is a center rest chuck. And they had a collet closer similar to what I'm wanting to make.

Looks like odd looking chuck is a center rest chuck. And they had a collet closer similar to what I'm wanting to make.

Last edited: