-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

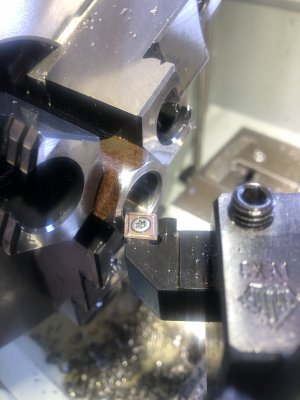

First Try at Metric Threading

- Thread starter erikmannie

- Start date

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Sep 8, 2019

- Messages

- 4,392

So this time I was not at all aggressive with the DOC. The most I ever did was .005” radial, but I noticed that I was getting so many chips on the spring passes that I just start doing radial cuts of .002” max. You wouldn’t believe how many chips I was getting even on a third or fourth spring pass: it’s a mystery.

Surprisingly, I tested the nut after coming out only .04275”, and the nut could be hand tightened (with difficulty) all the way in.

I was very generous with the oil-based CF.

I’m going to go back to where I was and just do spring passes. I wonder if the insert will ever come out clean.

Surprisingly, I tested the nut after coming out only .04275”, and the nut could be hand tightened (with difficulty) all the way in.

I was very generous with the oil-based CF.

I’m going to go back to where I was and just do spring passes. I wonder if the insert will ever come out clean.

Last edited:

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Sep 8, 2019

- Messages

- 4,392