- Joined

- May 20, 2013

- Messages

- 390

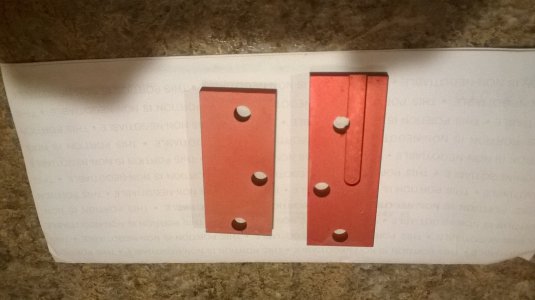

Spent a little time today trying my hand at anodizing. I had made a couple plates to help hold a poly AR15 80% lower while milling it out and thought I would see if I could anodize them. I had picked up some drain cleaner to etch the parts with and some pool PH reducer (Sodium Bisulphate) for the electrolyte. I found a piece of .062 aluminum sheet that i bent into an L shape for the cathode. I used an ice cream pail (small square one) as my anodizing tank. I mixed the PH reducer with water (just used plain tap water for now) and put the parts into a small plastic container with some water and drain cleaner in to etch. Used a 2 liter pop bottle to mix the electrolyte in and mixed as much as i could get to dissolve in warm tap water. Took the parts out of the etch and rinsed them, and hung one on a small piece of aluminum wire. I used an HP lab power supply so I could control the voltage and current. After a couple attempts, I found that for my small parts, I needed to run about 600 ma at around 10 volts into the parts for about an hour, then rinse in cold water and put into a dye made with RIT liquid dye in warm water for about 5 minutes or so, then rinse and into a pan of boiling water. I need to get some heavier wire and some distilled water, but the results were very promising. Here are the two parts after I finished: