- Joined

- Oct 13, 2014

- Messages

- 7,138

10" South Bend Tool Room lathe, needs a bath.

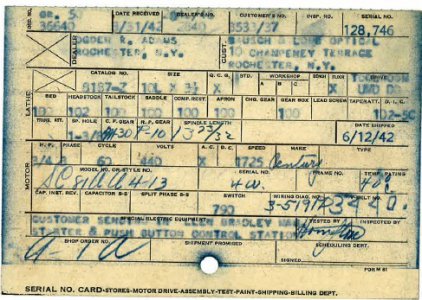

I scored a deal a 10" X 3 1/2' toolroom lathe off of CL a couple of weeks ago, Model 8187-Z. It has a placard indicating its a WWII era machine. It was, still is partially, covered in caked on grease and filth but no signs of rust, there are a couple of dings in the ways near the tailstock that will need to be scraped out but otherwise she looks pretty decent. Anyway, its a big upgrade from my 9"x3' change gear, bench model. It probably needs a complete teardown and rebuild but I have way too much on my plate right now and it will have to wait. In the meantime, I just want to get it up and running well enough to get me through my CNC Mill conversion that's looming in the near future,

So far, I spent about 8 hrs. just cleaning the cross/compound, tail stock 3/J chuck and main gear train. I have yet to do the motor compartment, QC gearbox, back gears, chip pan… I have been using a mixture of WD-40 and Mineral Spirits and various brushes to cut the filthy grease to but its slow going, Does any one know a faster way to clean this beast?

I had a couple of other questions as well:

I need to replace the V belt between the motor and countershaft it is very badly worn with cords sloughing off of it. I cut it and measured its length @ 43” and the top of the pulley is ⅝” wide, so the assumption is its a 5L 430. However it was so old I was wondering if it could have stretched at all and I need a shorter 5L 420 instead?

Also, the lathe is in my “dream shop” located in in my retirement home to be, about 100 miles north of where I live. I forgot to measure the threads on the set screws that lock the dials on the cross/compound feeds, before I left Sunday. I want to order some small thumb screws and the belt from McMaster before I go back up next weekend. Any help would be greatly appreciated.

Eddy

I scored a deal a 10" X 3 1/2' toolroom lathe off of CL a couple of weeks ago, Model 8187-Z. It has a placard indicating its a WWII era machine. It was, still is partially, covered in caked on grease and filth but no signs of rust, there are a couple of dings in the ways near the tailstock that will need to be scraped out but otherwise she looks pretty decent. Anyway, its a big upgrade from my 9"x3' change gear, bench model. It probably needs a complete teardown and rebuild but I have way too much on my plate right now and it will have to wait. In the meantime, I just want to get it up and running well enough to get me through my CNC Mill conversion that's looming in the near future,

So far, I spent about 8 hrs. just cleaning the cross/compound, tail stock 3/J chuck and main gear train. I have yet to do the motor compartment, QC gearbox, back gears, chip pan… I have been using a mixture of WD-40 and Mineral Spirits and various brushes to cut the filthy grease to but its slow going, Does any one know a faster way to clean this beast?

I had a couple of other questions as well:

I need to replace the V belt between the motor and countershaft it is very badly worn with cords sloughing off of it. I cut it and measured its length @ 43” and the top of the pulley is ⅝” wide, so the assumption is its a 5L 430. However it was so old I was wondering if it could have stretched at all and I need a shorter 5L 420 instead?

Also, the lathe is in my “dream shop” located in in my retirement home to be, about 100 miles north of where I live. I forgot to measure the threads on the set screws that lock the dials on the cross/compound feeds, before I left Sunday. I want to order some small thumb screws and the belt from McMaster before I go back up next weekend. Any help would be greatly appreciated.

Eddy

Last edited: