- Joined

- Sep 7, 2019

- Messages

- 674

Hey! I decided to start a separate thread to document the mailing tube rocket build. Thanks to @rwm for this cool idea!

So here's a quick recap, on what I've done so far...

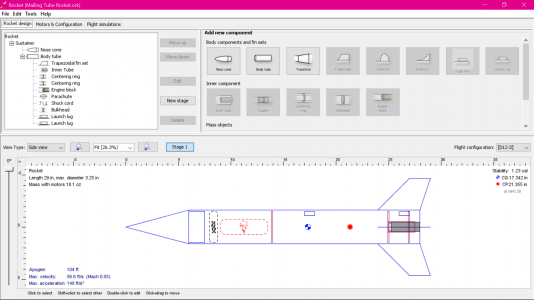

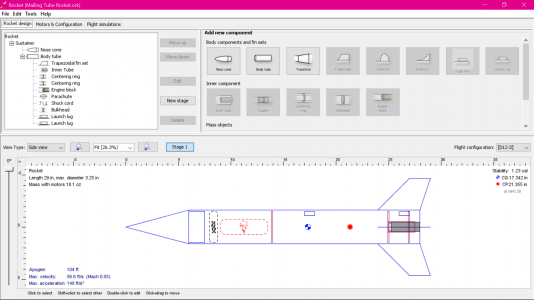

First is a screen capture of the Open Rocket file I made. This configuration seemed to have the best compromise of stability, speed off the rod, and total apogee. It also conforms to the general rule of at least 5:1 thrust to weight ratio. The body tube is 22" long with a 6" conical balsa nose cone with 1.5" shoulder. Rings and bulkheads will be 1/8" ply. Motor is Estes D12-3. Fins will be 0.080" acrylic sheet because I have some laying around.

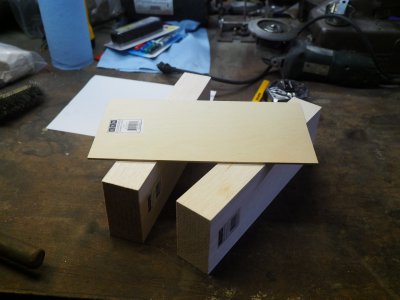

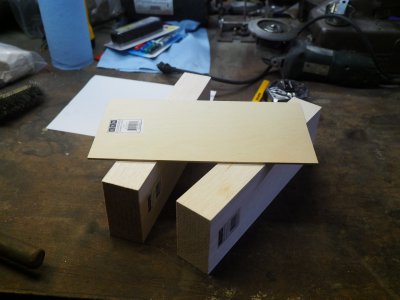

Here's the meterials I gathered. 2x4x12" balsa for the cone and 1/8" ply for the rings. Shout out to Bill and Walt's Hobby Shop in White Oak, PA! You can buy balsa online from them here.

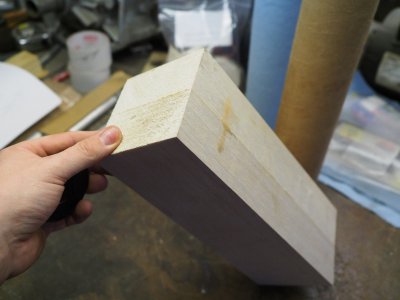

I glued and clamped the 2x4s together to make a 4x4. I can whittle this down to a 3.25" diameter nose cone.

Next made a motor tube. It's just some heavy packing paper wrapped with wood glue. I used a motor as a mandrel. The motor ended up a tiny bit loose, it may need a wrap or two of masking tape on launch day.

The ends will be cut off and cleaned up later.

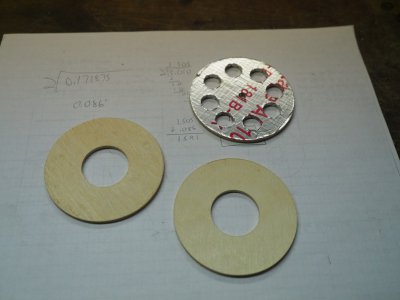

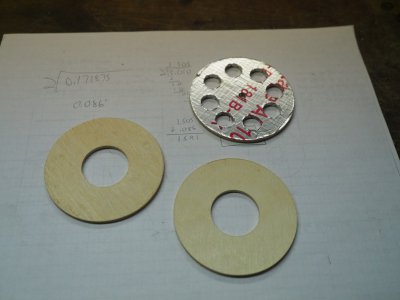

Next I began work on the rings and bulkhead. I used an old school fly cutter. I worked really well!

The fit is very good!

Next I cut the center holes with the fly cutter and a few holes in the bulkhead with a 1/2" forstner bit to pass the ejection charge. I also put a layer of foil tape on the motor side of the bulkhead, just in case it would want to scorch. The math is to set the fly cutter BTW.

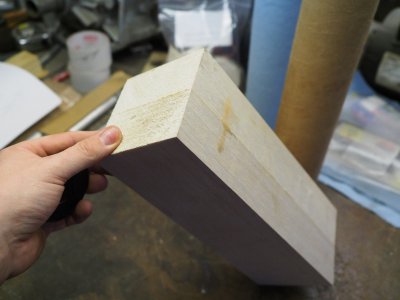

Here's the balsa block really for shaping. I think I'll cut it down to about 3.5" square then shave off the bulk of the cone with a draw knife of spoke shave. Then I'll probably do the dowel trick that @brino suggested.

More to come!

So here's a quick recap, on what I've done so far...

First is a screen capture of the Open Rocket file I made. This configuration seemed to have the best compromise of stability, speed off the rod, and total apogee. It also conforms to the general rule of at least 5:1 thrust to weight ratio. The body tube is 22" long with a 6" conical balsa nose cone with 1.5" shoulder. Rings and bulkheads will be 1/8" ply. Motor is Estes D12-3. Fins will be 0.080" acrylic sheet because I have some laying around.

Here's the meterials I gathered. 2x4x12" balsa for the cone and 1/8" ply for the rings. Shout out to Bill and Walt's Hobby Shop in White Oak, PA! You can buy balsa online from them here.

I glued and clamped the 2x4s together to make a 4x4. I can whittle this down to a 3.25" diameter nose cone.

Next made a motor tube. It's just some heavy packing paper wrapped with wood glue. I used a motor as a mandrel. The motor ended up a tiny bit loose, it may need a wrap or two of masking tape on launch day.

The ends will be cut off and cleaned up later.

Next I began work on the rings and bulkhead. I used an old school fly cutter. I worked really well!

The fit is very good!

Next I cut the center holes with the fly cutter and a few holes in the bulkhead with a 1/2" forstner bit to pass the ejection charge. I also put a layer of foil tape on the motor side of the bulkhead, just in case it would want to scorch. The math is to set the fly cutter BTW.

Here's the balsa block really for shaping. I think I'll cut it down to about 3.5" square then shave off the bulk of the cone with a draw knife of spoke shave. Then I'll probably do the dowel trick that @brino suggested.

More to come!