Alright, well, I got busy yesterday and didn't post my update, so today is a double feature!

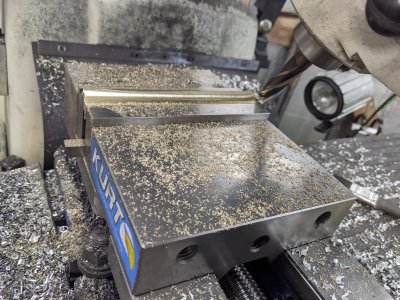

First, for these lead screw brackets, I flattened the outside to thickness:

Next, I found the center of the boss best I could, since the rest of the measurements are based on that:

Finally, I drilled and reamed the lead screw hole, and used the DRO for the mounting holes. The crossfeed mount is a little different (since a quadrant attaches to it), so those holes also got countersunk. One gotcha: 2 of them are 400 thou between the mount holes and leadscrews, the other is .325. the plans say match drill, so this is where I had to pay attention!

After that, a test fit with these on the whole 3 axis setup:

I made a mandrel in the lathe with a 3/8" center to mount these so I could turn the OD. While drilling the end, I untwisted a #7 drill!

And here is the big one mounted on the mandrel. The OD mattered, and the depth didn't as much, but all are turned the same way. I used some bearing retainer loctite which stickied up just enough in 10 mins to hold the part still.

After doing all 3, here they are:

That was the end of yesterday!

Today, I needed to do the back feature, where a thrust bearing is sandwiched between the mount and the lead screw shoulder. I was able to get them setup easily enough in the 4 jaw, and bored it out, a bit more than .300 deep, and .800 around for clearance. The stack up is only .265, so there is plenty of depth.

After all 3;

Then, I started on another part: the feed quadrant, which holds gears to power the gear through the cutter. First operation was a but precarious, but I was able to flatten it well enough. My casting was a bit pretzelly, so in the end I end up about 40 thou too thin, but hopefully that doesn't cause problems.

Next, I flipped it over onto a fixture plate I made a while back, and milled the other side flat, moving clamps mid way through:

I used the boring head to get a tight fit on the lead screw mount:

Finally, drilled the clamp hole, used the cut off wheel to make it a clamp, then went back and clearance drilled the top, then tapped:

And, done, clamped onto the mating part:

And, that's it! All the castings in the "main tower", and all but 2 of the castings total! One of which I need a replacement, the other of which is another quadrant that attaches to that (so I have some adjustments I can use cutting it differently).

I'm on the fence whether I intend to drive the hour each way to pick up the replacement casting right away, or if I want to just start making the rest of the parts to assemble the main tower. What do you all think?