- Joined

- Jan 1, 2011

- Messages

- 305

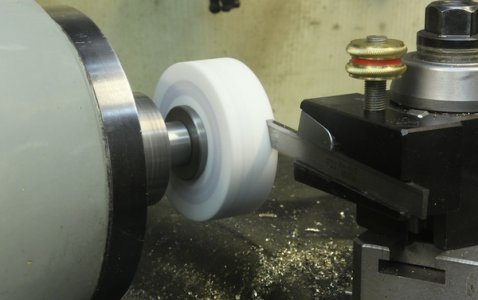

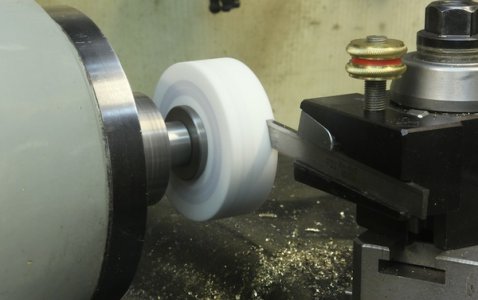

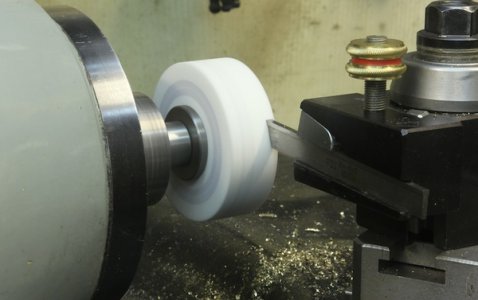

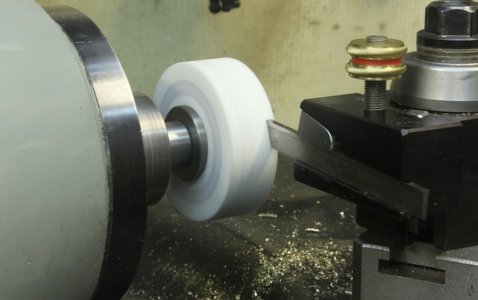

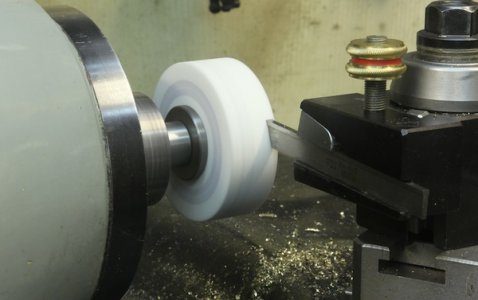

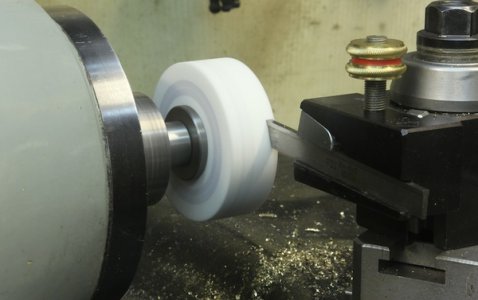

Over the years I've gotten lots better at offhand grinding of HSS lathe tools, but lately I've been thinking of making a setup for my grinder to be a bit more precise. Then, this morning I hit on what I suppose is a relatively obvious idea. Why not grind the end of my cutoff tool right on the lathe so I'd be dead sure of getting it precisely square to the work? So I stuck a white wheel in an arbor, raised the tool well above center, moved along the Z axis and dusted off the end to get a nice sharp perfectly square cutting edge:

I keep that rubber sheeting on the lathe, so I didn't have to set up any special grinding dust protection.

I keep that rubber sheeting on the lathe, so I didn't have to set up any special grinding dust protection.