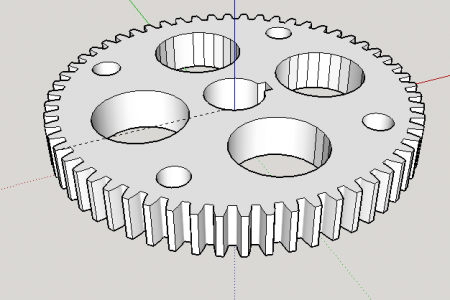

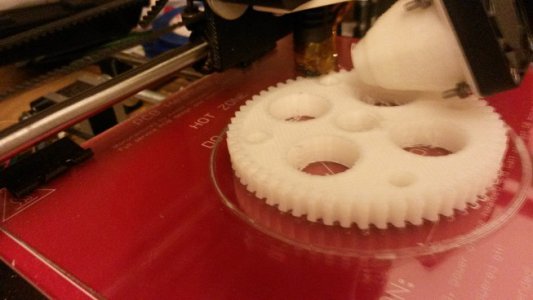

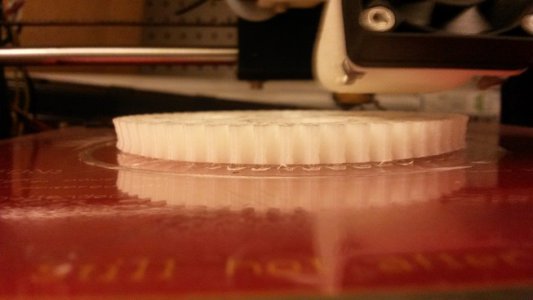

I did something similar on my South bend 9a, by using a 26t stud gear to replace the 20t, I was able to cut 1.5mm with only .06% error. The gear can easily be made on the lathe if you grind your own form tool and slot the teeth (I used PVC, Nylon should work as well). Make an index wheel for your spindle and rig up a pointer: http://www.cgtk.co.uk/metalwork/divider

A few pics of the process: http://s1182.photobucket.com/user/martik777/library/Making gears from PVC or Delrin?sort=9&page=1

Here are a few other combos from a program I wrote (modified for your Logan - please double check the results)

Stud 24 Screw 41 Pos: B3 Error (mm/%) 0.013 / 0.88% Actual:1.48683

Stud 24 Screw 45 Pos: B2 Error (mm/%) 0.005 / 0.35% Actual:1.50519

Stud 24 Screw 51 Pos: B1 Error (mm/%) 0.006 / 0.39% Actual:1.49412

Stud 24 Screw 58 Pos: A8 Error (mm/%) 0.001 / 0.10% Actual:1.50148 *** Did u miss this one?

Stud 24 Screw 62 Pos: A7 Error (mm/%) 0.013 / 0.84% Actual:1.51266

Stud 24 Screw 63 Pos: A7 Error (mm/%) 0.011 / 0.76% Actual:1.48864

Stud 24 Screw 68 Pos: A6 Error (mm/%) 0.006 / 0.39% Actual:1.49412

Stud 24 Screw 70 Pos: A5 Error (mm/%) 0.015 / 0.97% Actual:1.51453

Stud 24 Screw 71 Pos: A5 Error (mm/%) 0.007 / 0.45% Actual:1.49320

Stud 24 Screw 74 Pos: A4 Error (mm/%) 0.002 / 0.15% Actual:1.49779

Stud 20 Screw 48 Pos: A8 Error (mm/%) 0.012 / 0.79% Actual:1.51190

Stud 31 Screw 48 Pos: B4 Error (mm/%) 0.009 / 0.58% Actual:1.49129

If you want combos for other pitches let me know

A few pics of the process: http://s1182.photobucket.com/user/martik777/library/Making gears from PVC or Delrin?sort=9&page=1

Here are a few other combos from a program I wrote (modified for your Logan - please double check the results)

Stud 24 Screw 41 Pos: B3 Error (mm/%) 0.013 / 0.88% Actual:1.48683

Stud 24 Screw 45 Pos: B2 Error (mm/%) 0.005 / 0.35% Actual:1.50519

Stud 24 Screw 51 Pos: B1 Error (mm/%) 0.006 / 0.39% Actual:1.49412

Stud 24 Screw 58 Pos: A8 Error (mm/%) 0.001 / 0.10% Actual:1.50148 *** Did u miss this one?

Stud 24 Screw 62 Pos: A7 Error (mm/%) 0.013 / 0.84% Actual:1.51266

Stud 24 Screw 63 Pos: A7 Error (mm/%) 0.011 / 0.76% Actual:1.48864

Stud 24 Screw 68 Pos: A6 Error (mm/%) 0.006 / 0.39% Actual:1.49412

Stud 24 Screw 70 Pos: A5 Error (mm/%) 0.015 / 0.97% Actual:1.51453

Stud 24 Screw 71 Pos: A5 Error (mm/%) 0.007 / 0.45% Actual:1.49320

Stud 24 Screw 74 Pos: A4 Error (mm/%) 0.002 / 0.15% Actual:1.49779

Stud 20 Screw 48 Pos: A8 Error (mm/%) 0.012 / 0.79% Actual:1.51190

Stud 31 Screw 48 Pos: B4 Error (mm/%) 0.009 / 0.58% Actual:1.49129

If you want combos for other pitches let me know

Last edited: