- Joined

- Jul 29, 2014

- Messages

- 2,737

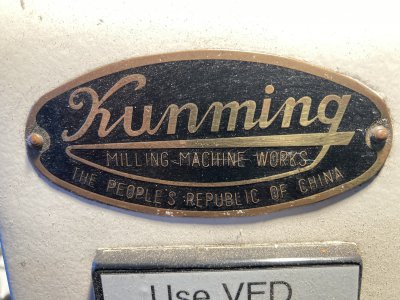

You know what they say about broken clocks. I'm curious, about the name on your machine. Is it Kao Ming? That would be significant, they are a maker of grinding machinery in Taiwan that plays reduced budget competition to some major toolmakers like KO Lee and Cinci. Was it a new or used purchase?

It's a Kunming, clearly mainland Chinese. Seems well built and is very functional. I need to get the U3 head placed and finish some wheel hubs for inexpensive diamond cup wheels.