If you don’t have the capability to make a gear, you should be able to modify one easy enough to fit. Figure out what module the gears are on your lathe, then go to Maedler Gear and see if they have one of the right size, or close enough that you could make it fit.

maedlernorthamerica.com

maedlernorthamerica.com

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting 11.5 TPI threads

- Thread starter LROYSON

- Start date

If I find a 23 tooth gear that works on my lathe were would it need to be placed in the gear train (I assume it would replace the 30 or 60 tooth gear as per the chart) and what tpi settings would you set the dials to? Thanks again for everyone's help I am learning here so forgive me if my questions are elementary.

- Joined

- Nov 23, 2014

- Messages

- 2,607

You're not alone on this topic. I'm following as I'd like to do 27 tpi with a gear box that goes from 26 to 28.If I find a 23 tooth gear that works on my lathe were would it need to be placed in the gear train (I assume it would replace the 30 or 60 tooth gear as per the chart) and what tpi settings would you set the dials to? Thanks again for everyone's help I am learning here so forgive me if my questions are elementary.

Bruce

- Joined

- Jun 7, 2013

- Messages

- 10,101

Read my earlier post! I used the method to do 19 and 27 TPI on my 19" Regal that would cut neither as built.You're not alone on this topic. I'm following as I'd like to do 27 tpi with a gear box that goes from 26 to 28.

Bruce

If I find a 23 tooth

How did you determine a 23 tooth gearwould work?Likely a 23 tooth gear on the change box would do it.

- Joined

- Oct 14, 2013

- Messages

- 990

Amazon has Boston change gears; that's where my set came from GA23 might find it.

McMaster, of course

Sent from my SM-G715A using Tapatalk

McMaster, of course

Sent from my SM-G715A using Tapatalk

- Joined

- Nov 23, 2014

- Messages

- 2,607

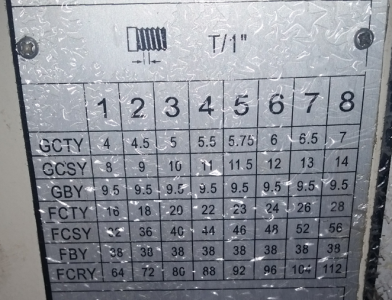

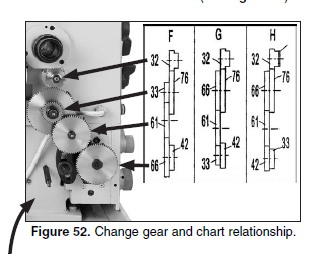

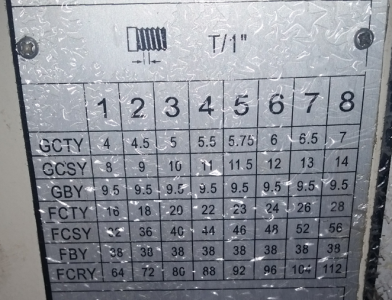

My Grizzly G0709 comes with what they call a "Universal Change Gear Box" which lets owners swap between English and Metric threading by the turn of a knob. I admit to not researching it well; looking at the parts lists for the headstock and QCGB I don't see a 127 tooth gear for a "perfect" conversion. Most likely one of the "close enough" combos of gears. Anyway, here's my threading chart and quadrant gears:

27 is 3 x 3 x 3 while 18 is 2 x 3 x 3 (yes, statements of the obvious); ratio between the two is 3 to 2 (factor out the 9's). I thought about replacing my 66 (2 x 3 x 11) tooth gear with a 44 (2 x 2 x 11) tooth gear in gear box setting "F" to speed things up by 1.5 and take 36 tpi down to 27 tpi? I'm thinking the faster the lead screw turns relative to the spindle, the coarser the thread. Spinning the lead screw faster by 1.5 should result in a coarser thread. I know my math is off because 36 / 1.5 is 24, not 27. . . So I really need a ratio of 1.3333?

Am I thinking this through correctly?

Bruce

27 is 3 x 3 x 3 while 18 is 2 x 3 x 3 (yes, statements of the obvious); ratio between the two is 3 to 2 (factor out the 9's). I thought about replacing my 66 (2 x 3 x 11) tooth gear with a 44 (2 x 2 x 11) tooth gear in gear box setting "F" to speed things up by 1.5 and take 36 tpi down to 27 tpi? I'm thinking the faster the lead screw turns relative to the spindle, the coarser the thread. Spinning the lead screw faster by 1.5 should result in a coarser thread. I know my math is off because 36 / 1.5 is 24, not 27. . . So I really need a ratio of 1.3333?

Am I thinking this through correctly?

Bruce

- Joined

- Dec 18, 2019

- Messages

- 6,464

This stuff confuses me all the time. I don't know if this will help, but this is how I like to think about these kinds of problems.My Grizzly G0709 comes with what they call a "Universal Change Gear Box" which lets owners swap between English and Metric threading by the turn of a knob. I admit to not researching it well; looking at the parts lists for the headstock and QCGB I don't see a 127 tooth gear for a "perfect" conversion. Most likely one of the "close enough" combos of gears. Anyway, here's my threading chart and quadrant gears:

View attachment 448218View attachment 448217

27 is 3 x 3 x 3 while 18 is 2 x 3 x 3 (yes, statements of the obvious); ratio between the two is 3 to 2 (factor out the 9's). I thought about replacing my 66 (2 x 3 x 11) tooth gear with a 44 (2 x 2 x 11) tooth gear in gear box setting "F" to speed things up by 1.5 and take 36 tpi down to 27 tpi? I'm thinking the faster the lead screw turns relative to the spindle, the coarser the thread. Spinning the lead screw faster by 1.5 should result in a coarser thread. I know my math is off because 36 / 1.5 is 24, not 27. . . So I really need a ratio of 1.3333?

Am I thinking this through correctly?

Bruce

For a thread, lets use TPI for this discussion, 1 turn of the spindle should result in the carriage moving 1/(target TPI) [units = inches].

But we have a lead screw that is LSTPI. In general, LSTPI is not equal to the desired target thread TPI.

We need to solve for when N turns of the lead screw divided by the lead screw TPI is equal to the required distance for a single pitch of the thread. N/LSTPI = 1/(target_TPI). (units for both sides of the equation are inches) N is the gear ratio. N is obviously independent of speed. Reiterating:

N is the final gear ratio that is needed. More simply, N = (lead screw TPI) / (desired TPI) [units = dimensionless].

Hope this helps you determine what is needed. I had to go through a similar thought process when I was doing my own coding for my ELS. Using the basic idea above, really simplified things for me. [Watching my units helped a lot too! Cuts way down on massive screw ups when you do units checks.]