-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutoff blade holder-holder question

- Thread starter Reddinr

- Start date

- Joined

- Apr 8, 2013

- Messages

- 1,982

My cutoff is mounted horizontally and presented at neutral rake. If the machine is rigid enough you don't need back rake. My comment about welding a tool holder was addressed to a question on this thread regarding whether tool holders can be welded. My welding mod was to make a small milling attachment that could be mounted quickly with out going thru the hassle of mounting my larger unit.

Last edited:

- Joined

- Jan 5, 2014

- Messages

- 944

I bought a rocker tool post from Grizzly for the size Grizzly lathe I have. I spent an hour or so grinding the T-nut to fit since it was a generic piece (not unexpected). And I took off a hair from the diameter of the flange at the bottom of the tool post to fit. The problem is that there is too much meat in the compound above the T-nut so the rocker assembly won't fit the height of cut-off tool holder. It would if I just clamp it in without the rocker/bowl pieces but not with them in place. It will work if I keep the holder flat and not at an angle. I'll be giving that a try over the weekend. Good to know the holders weld up well. Will keep that info. in my back pocket for later.

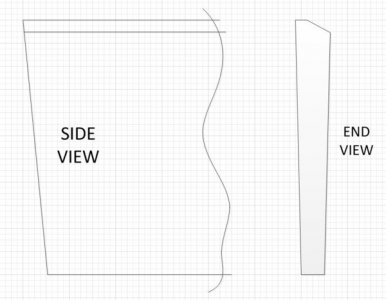

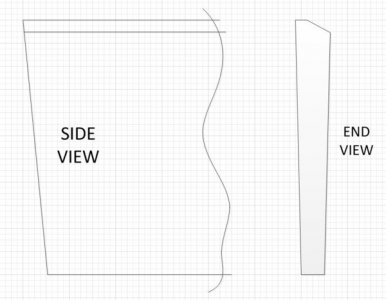

I noticed that my HSS cut-off blade has an odd profile on the top edge. Is this normal? Seems to me it might cause it to have more force to one side vs. the other. (See pic.) The top profile angle and depth has been exaggerated a little to make it show up better in the picture. The small cut-off blade I have does not have this type of profile.

This all started when I needed to make four little feet for a wood/metal stool I'm building... I figure about a day would do it. Cutting/welding entire frame for stool-3 Hours so I was feeling pretty good. Making the little feet-5 Hours and counting! I wasted some time by making some feet from some unknown metal I had. Had lots of worry about snapping the small cut-off blade making those. That metal did not weld in a nice way. Stool now 3/8" shorter after cutting off first badly welded disk foot.

I noticed that my HSS cut-off blade has an odd profile on the top edge. Is this normal? Seems to me it might cause it to have more force to one side vs. the other. (See pic.) The top profile angle and depth has been exaggerated a little to make it show up better in the picture. The small cut-off blade I have does not have this type of profile.

This all started when I needed to make four little feet for a wood/metal stool I'm building... I figure about a day would do it. Cutting/welding entire frame for stool-3 Hours so I was feeling pretty good. Making the little feet-5 Hours and counting! I wasted some time by making some feet from some unknown metal I had. Had lots of worry about snapping the small cut-off blade making those. That metal did not weld in a nice way. Stool now 3/8" shorter after cutting off first badly welded disk foot.

Aside from rigid setups most cut off problems are from a not a fast enough firm feeding. if it chatters feed faster with lots of pressure. 2 in dia start with .100 above center, when it quits cutting drop to center and finish. Lube,speed,firm fast feed.

4

4GSR

Forum Guest

Register Today

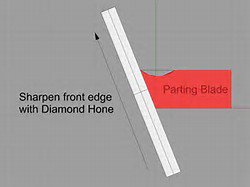

That type of blade you have to grind the top of the blade flat for about a 1/2" back, maybe even a little future. Just depends on the OD of the part you are trying to part off..............

I noticed that my HSS cut-off blade has an odd profile on the top edge. Is this normal? Seems to me it might cause it to have more force to one side vs. the other. (See pic.) The top profile angle and depth has been exaggerated a little to make it show up better in the picture. The small cut-off blade I have does not have this type of profile.................

View attachment 234231

4

4GSR

Forum Guest

Register Today

That beveled edge is what bears against the screw or bolt that secures the blade in the holder. It's always been like that until someone came out the "T" shaped blade. Now the T-blade doesn't really fit old style holder properly, not even a Aloris No. 7 holder. But most of us use it that way. To use the T-blade in a conventional holder, a shim needs to be inserted the base of the T-Blade and the side wall of the holder. Doing this will keep the blade square to the work and not worry about the bottom of the blade dragging against the work piece while parting off.dlane. Wow, what a great idea! 4gsr, any idea why they supply the blade that way? Grinding is easy but why?