-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cnc plasma

- Thread starter Traian

- Start date

AC servos were for the huge plasma. The owner (and I) didn't want steppers on a 12' x 6' industrial machine. It's a big machine and he wanted it FAST.you have Ac servo drive

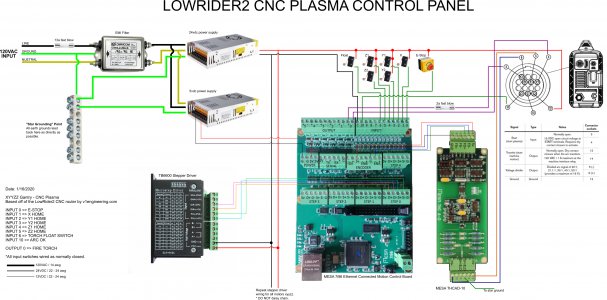

The other enclosure is for the stepper-driven smaller table I mentioned earlier in the thread. Works great - aside from one loose drive pulley (set screw), there have been zero issues since it was commissioned. Not one!

Hi Ralphi found in europe something about integrate servo motor with low inductance, witch i understand is better

www.rocketronics.de

and other https://www.rocketronics.de/shop/en/hybridservodriver-es-d808.html

www.rocketronics.de

and other https://www.rocketronics.de/shop/en/hybridservodriver-es-d808.html

i can found 8 nm nema 34 closed loop, least can provide data sheet and support

trying to go away from eBay as said. thanks

JMC servo motor with integrated driver 400 Watt and software version 6

Integrated servomotor with 400W from JMC ✓3000 rpm ✓Latest software 604 ✓NEMA24 ✓for CNC and automation ✚ Immediate delivery ✚ 30 days return policy ➨Order now!

i can found 8 nm nema 34 closed loop, least can provide data sheet and support

trying to go away from eBay as said. thanks

I tend to shy away from integrated drive/motor combinations. If one of the two components (usually the drive) has issues you have to scrap both items. Motors rarely die.

I think you'd be happier with some Nema 23 or 34 closed loop steppers like you posted earlier. When I suggested "stay away from ebay" I was referring to the no-name vendors. StepperOnline is not a 'no-name' vendor.

The steppers will have much more torque at low RPM than similar-sized 48v servos. This means you don't need a complicated and expensive drive reduction system. A simple 3:1 belt reduction will be sufficient for speed and acceleration using steppers. A small servo will likely need a 5:1 or greater reduction to get the same torque.

I think this would be perfect for a small table. It's essentially what's on the first one I built:

https://www.omc-stepperonline.com/c...4-motor-and-driver.html?mfp=16o-ship-from[61]

I think you'd be happier with some Nema 23 or 34 closed loop steppers like you posted earlier. When I suggested "stay away from ebay" I was referring to the no-name vendors. StepperOnline is not a 'no-name' vendor.

The steppers will have much more torque at low RPM than similar-sized 48v servos. This means you don't need a complicated and expensive drive reduction system. A simple 3:1 belt reduction will be sufficient for speed and acceleration using steppers. A small servo will likely need a 5:1 or greater reduction to get the same torque.

I think this would be perfect for a small table. It's essentially what's on the first one I built:

https://www.omc-stepperonline.com/c...4-motor-and-driver.html?mfp=16o-ship-from[61]

hi

i know i have few idea been told to not use hgr rails but i was thing to use existing one because instant to buy other rails,buy something else don't have.

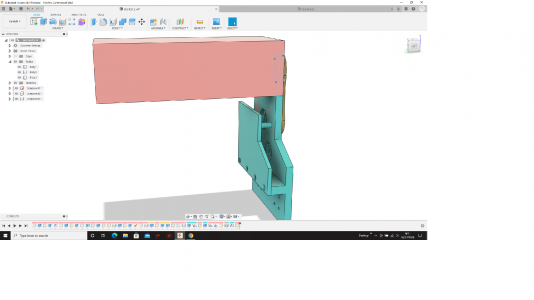

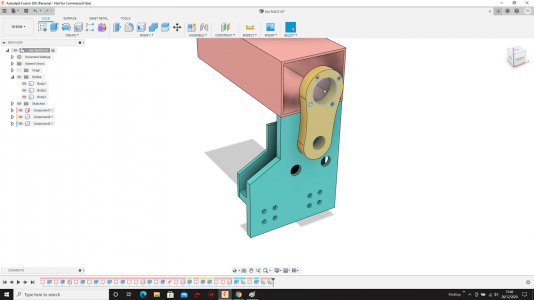

i have been drawing a section of gantry and my intention is to fit stepper inside the gantry, I don't know if will affect change direction in acceleration, the belt i will using will be AT5 32mm wide. sorry for my drawing is beginner.

or shell i fit the motor in the bottom? thanks

i know i have few idea been told to not use hgr rails but i was thing to use existing one because instant to buy other rails,buy something else don't have.

i have been drawing a section of gantry and my intention is to fit stepper inside the gantry, I don't know if will affect change direction in acceleration, the belt i will using will be AT5 32mm wide. sorry for my drawing is beginner.

or shell i fit the motor in the bottom? thanks

Attachments

Put it behind or on top of the gantry. Fitting it inside will be a pain, it will not get as much cooling, and maintenance on the motors will be impossible without significant disassembly.

The HRD (or other profile) rails are fine, but they require quite a bit more care during the frame construction. If everything isn't extremely flat/straight, they bind up or wear out much more quickly. That's why I suggested bearing rollers - they're more tolerant of misalignment.

The HRD (or other profile) rails are fine, but they require quite a bit more care during the frame construction. If everything isn't extremely flat/straight, they bind up or wear out much more quickly. That's why I suggested bearing rollers - they're more tolerant of misalignment.