Hi guys

Here is a problem I hope those who are well versed in the art of making electrify do what they want it to do. I would like to hook the newly acquired Clausing / Colchester VS 12” up to a Hunghang VFD.

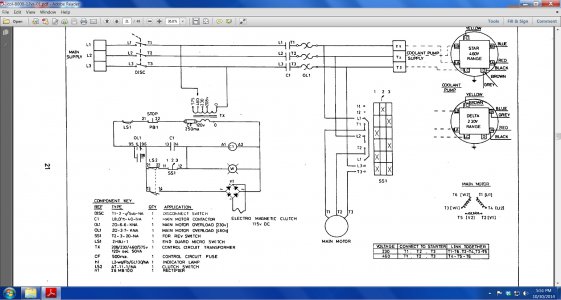

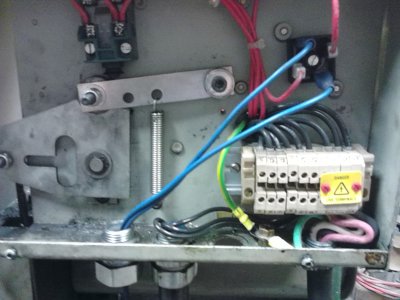

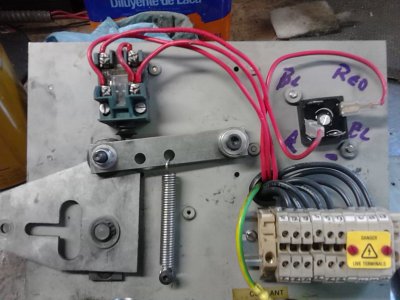

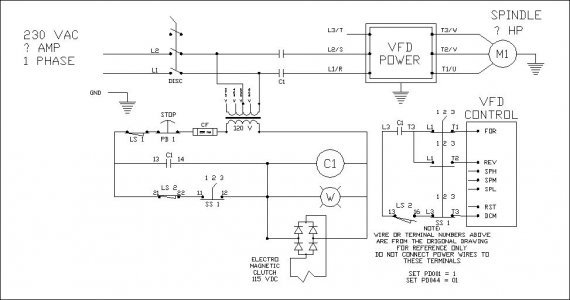

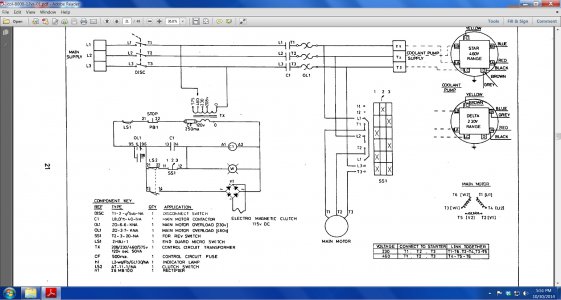

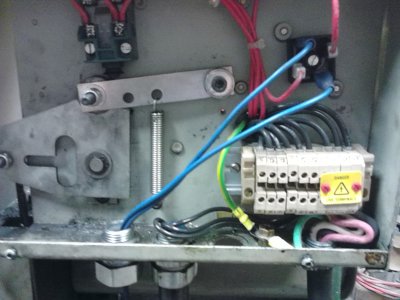

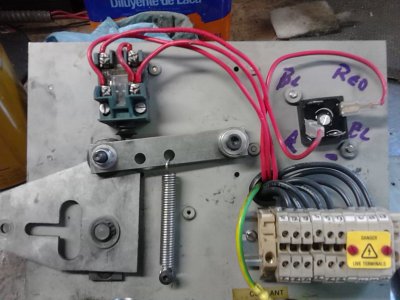

I am including a wiring diagram and pic’s of the electric components.

I want to be able to use the front panel controls on the lathe to run it, I know, no sweat just trash all the wiring and wire the control wires from the VFD to the switches. (like I did on my Vorest Lathe.

I need to use the transformer and some of the “other stuff” to control the electric clutch (110v dc from the transformer), the E switch and darn if I know what else.

I assume (dangerous word) I will need to hook up the 220 1phase to the “off-on” switch and then to the VFD but I’m lost from there.

Any help out there??

Here is a problem I hope those who are well versed in the art of making electrify do what they want it to do. I would like to hook the newly acquired Clausing / Colchester VS 12” up to a Hunghang VFD.

I am including a wiring diagram and pic’s of the electric components.

I want to be able to use the front panel controls on the lathe to run it, I know, no sweat just trash all the wiring and wire the control wires from the VFD to the switches. (like I did on my Vorest Lathe.

I need to use the transformer and some of the “other stuff” to control the electric clutch (110v dc from the transformer), the E switch and darn if I know what else.

I assume (dangerous word) I will need to hook up the 220 1phase to the “off-on” switch and then to the VFD but I’m lost from there.

Any help out there??