More progress was made on the table feed and gear housing assembly.

I started at the left side where the power feed goes, this end was already disassembled a bit from braking the machine down when I brought it home 7 month ago. Turns out the left side of the table was the appropriate choice to break down because the bearing is not retained in the dial housing which is those caps that go on the end of the table. The R/H side of the table has two bearings that are retained by a metal plate, so it's a little more difficult to take apart.

Turns out there's a whole bunch of spacers that go between the dial and the bearing, not sure what's up with that, I suspect it has to do with alignment of the power feed drive gear.

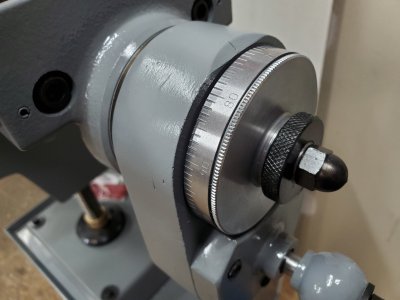

Next I moved on to the R/H side of the table lead screw, which on the 8530 has the rapid feed gear housing assbly.

Removing the cover on the gear housing, revealed that the grease inside had actually hardened to the point it could be chipped off with a scrapper. I would guess this is the original grease put on there 54 years ago. Nothing a little boiling hot Simple Green Extreme (SGE) bath in the ultrasonic tank won't tank care of. I've become very keen to checking if parts are ferrous, ever since the tragedy with the aluminum wiper retainers disappearing into the caustic hot tank forever. If the magnet don't stick or I see any sort of copper/bronze/brass bushings on there, then they get the SGE spa treatment.

Here the gear housing is all opened up and removed from the dial housing. You can see that plate retaining the bearings in the dial housing, it's the same setup used on the cross feed screw.

Here's a little lesson I learned the hard way. I tried pulling the bearings, plate and gear off the screw all at the same time, using my bearing separator. I was tightening it by hand and could feel the bearings start to move, but then get fetched up and the sudden it's much harder to turn.

Turns out and it's obvious now that this would be the case, but there's a woodruff key under that gear, so it needs to be pulled first, then the key removed, then the bearings. You can see where the inner race of the bearing smashed up the key pretty bad. I was going to replace the bearings anyways, so no big deal there, but a new key had to be sourced from McMaster Carr P/N: 98481A075.

Then between the bearings there's a spacer, which also got beat up pretty bad in my bumbling about with the bearing separator. I determined the closest match was McMaster Carr P/N:

3088A232.

Finally the bearings were off the shaft...

I pulled the handle off the end of the gearbox shaft, only to discover that the woodruff key had been wobbling about in there widening out the keyway. Not sure why this happened and I was pretty worried that I'd have to make some repairs here.

There was a bit of damage on the keyway inside the handle as well.

I ended up just filing down the raised edges around the shaft keyway, installing one of those new keys I bought, and hammering the handle back on there. No signs of it wobbling about yet, but I'll have to keep an eye on it.

The lock wheel was sealed up on the dial, maybe if I'd tried removing it before disassembly it would have been easier, but I came up with this clever method of clamping it in the vice and using cannon plug pliers to break it loose without causing any damage.

I wish I could have saved this little sticker on the gearbox cover, but u had to be removed to properly clean the cover. I figured I might be able to recreate it if I took pictures with a scale.

Here's all the parts cleaned up and ready for reassembly. Disregard the large bolts and rectangular plate. Those are for the lathe.

First the two gear stack went in.

Then the shaft with associated gears. I chose to lube it with Lucas Red "N" Tacky #2 because it's what I had and it seemd appropriate.

Guess I thought this photo may be helpful to show the set screw retaining the shaft which the two gears ride on.

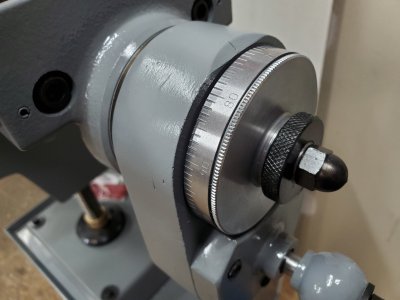

Here it is all finished up.