0

09kevin

Forum Guest

Register Today

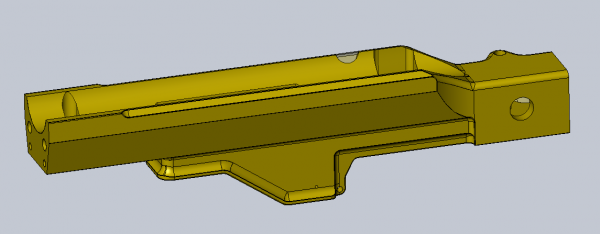

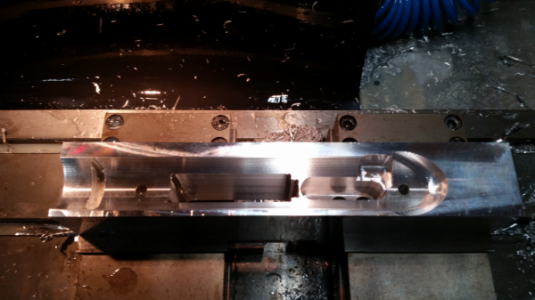

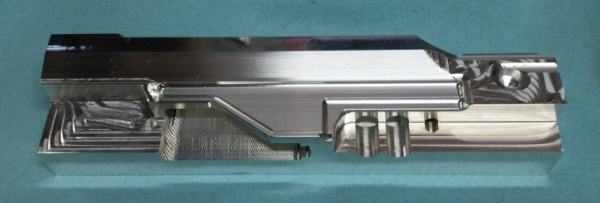

Hi Jay. Nice looking parts!

Kevin

Kevin

Last edited by a moderator:

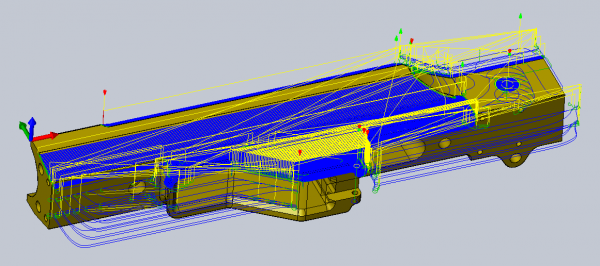

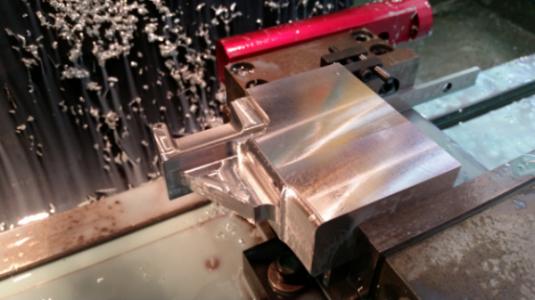

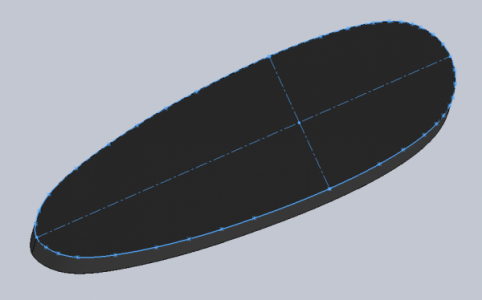

Hello. The recoil pad how did you go about modeling it/measuring to get the profile so perfect ?

Sent from my iPhone using Tapatalk

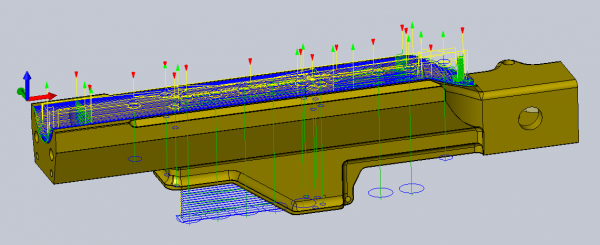

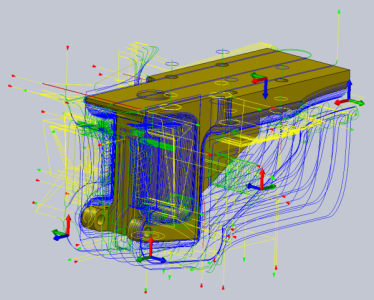

Looks good Jay! I noticed that you were playing with the 4th axis in another post, have thought about using it on some of these parts?

Kevin