- Joined

- Dec 3, 2013

- Messages

- 1,844

This will be a build log for a tactical rifle chassis build. I figure since most of the manufacturing will be done on my CNC converted PM-932 I would post it in the CNC forum.

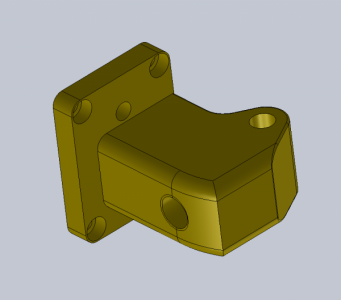

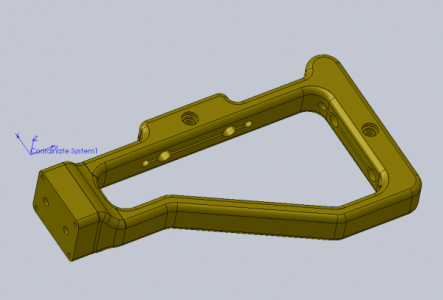

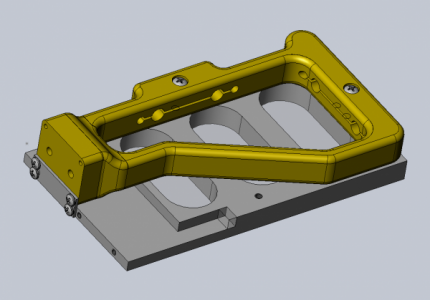

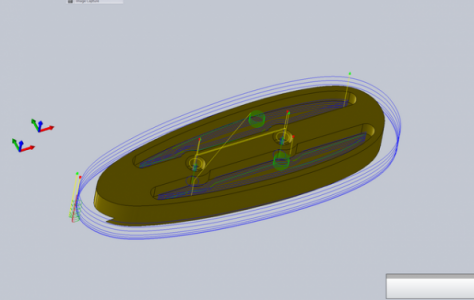

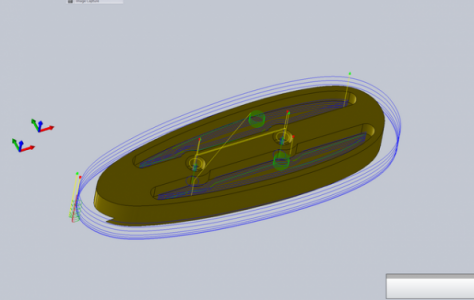

This is the CAD model I did in Solidworks. The chassis is loosely based on the Remington MSR. This is setup for a Rem 700 short action receiver.

I started with the easiest parts, the butt pad mount and slide.

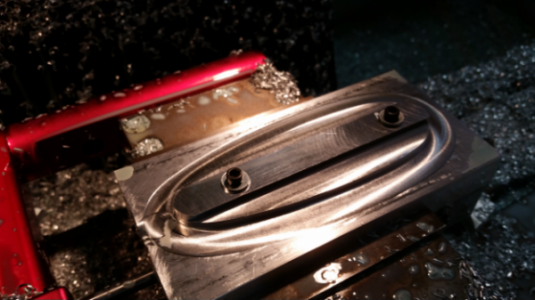

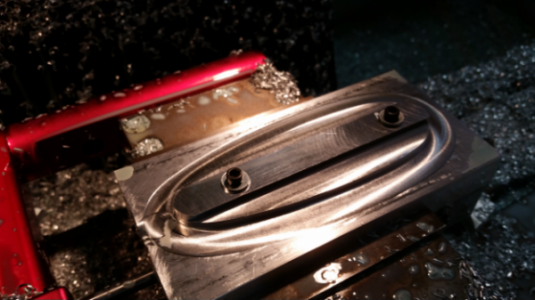

The mount has ops on both sides so those were done in the vise. The perimeter was done by bolting it to a fixture held in the vise. The slide was drilled then bolted on the same fixture to do the perimeter and dovetail.

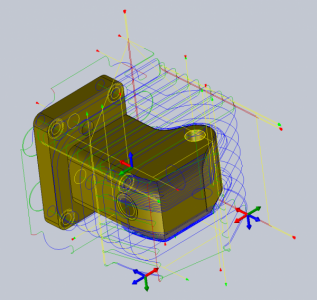

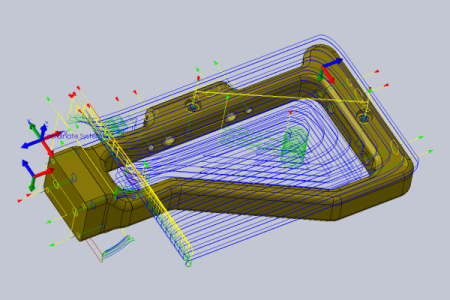

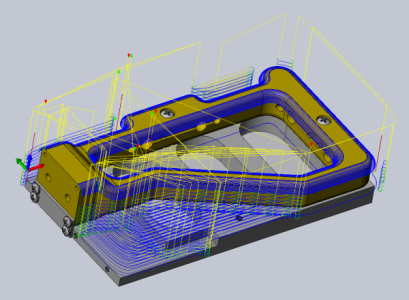

Tool paths in HSM Express.

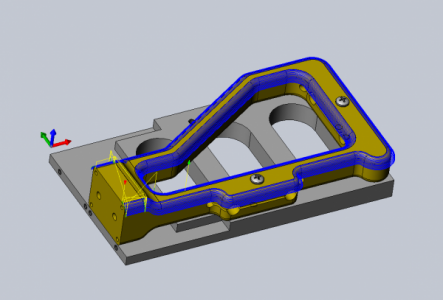

Completed slide on fixture.

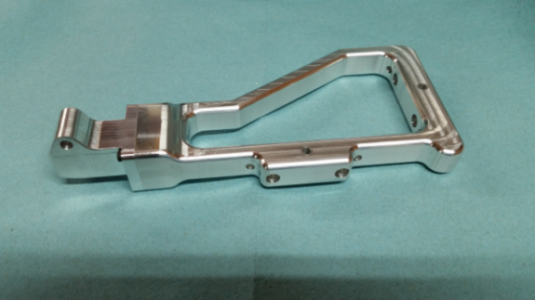

Completed mount and slide.

The parts get more complicated from here so figuring out the work holding will be a challenge.

This is the CAD model I did in Solidworks. The chassis is loosely based on the Remington MSR. This is setup for a Rem 700 short action receiver.

I started with the easiest parts, the butt pad mount and slide.

The mount has ops on both sides so those were done in the vise. The perimeter was done by bolting it to a fixture held in the vise. The slide was drilled then bolted on the same fixture to do the perimeter and dovetail.

Tool paths in HSM Express.

Completed slide on fixture.

Completed mount and slide.

The parts get more complicated from here so figuring out the work holding will be a challenge.

This is the 5th revision just in CAD. The final version may have some changes depending on how the parts come out or difficulty in machining.

This is the 5th revision just in CAD. The final version may have some changes depending on how the parts come out or difficulty in machining.