- Joined

- Jun 14, 2017

- Messages

- 263

I am wanting to be able to center-punch some steel, including some stainless steel as well down the road. Mostly for just getting a drill started into the metal.

I am curious, is something like this perfectly feasible for this?

https://www.princessauto.com/en/detail/5-pc-centre-punch-set/A-p8548075e

If so, I'll grab a pack.

I am curious, is something like this perfectly feasible for this?

https://www.princessauto.com/en/detail/5-pc-centre-punch-set/A-p8548075e

If so, I'll grab a pack.

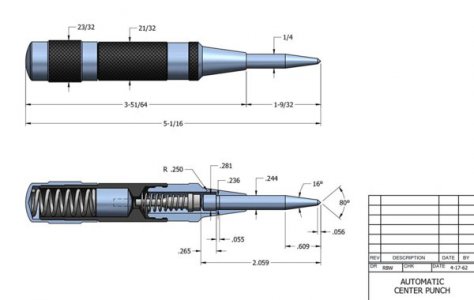

Buy 1 good punch and hammer away . I have many auto center punches but they are always out of reach when I need them , so I use anything hardened with a point . I guarantee your workpiece won't know the difference !

Buy 1 good punch and hammer away . I have many auto center punches but they are always out of reach when I need them , so I use anything hardened with a point . I guarantee your workpiece won't know the difference !