You can't just buy the SPG, because it might not be right.

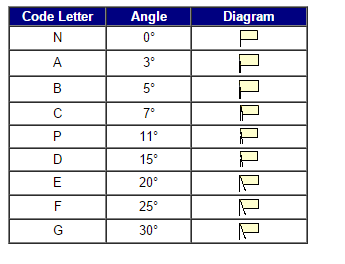

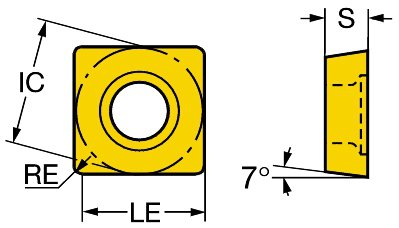

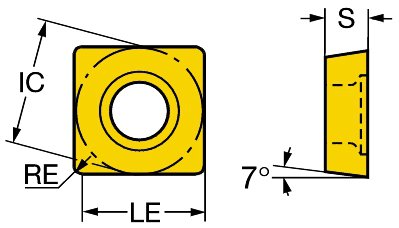

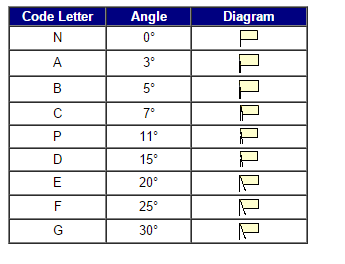

The P in SPG does not mean positive, though usually they are. P is the letter that designates an 11 degree relief angle. Face mills are designed for a specific angle insert to be used in them. If you don't pick the right one, you could damage the insert, because it doesn't seat correctly. You could also get a horrible finish because the insert is rubbing because it doesn't have enough clearance.

here are the other possibilities.

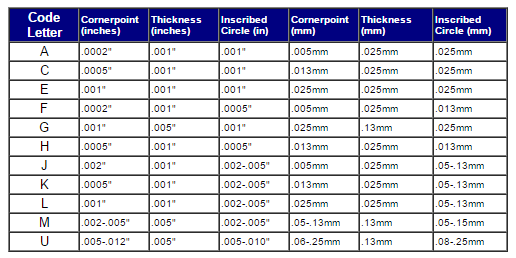

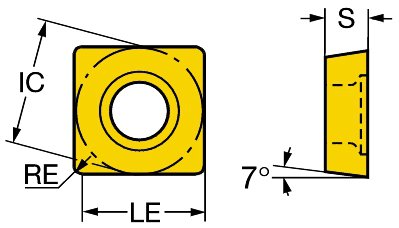

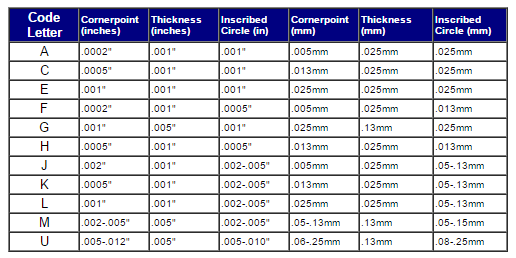

The G in SPG does not mean ground, it's the letter that designates a given tolerance. H & K are even tighter tolerances, and are what most of the 45 degree face mills calls for. If you are going to use a given mill for rouging, you can get away with say an M, and usually pay less. Here are the other designations.

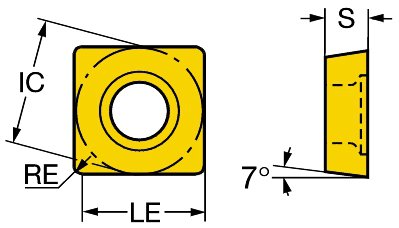

If you find an insert that fits that has a hole you can still use it as the hole will not effect your application. The holes are normally used with small positive rake inserts without a clamp or larger negative rake inserts with a clamp.

You need to be careful doing this, A lot of the alluminum specific inserts, have cutting edges higher than the center, and if you clamp down on them like you would for a hole less insert, you will damage the cutting edge.

Thanks wrek,so I should order spg422 1 is that for steel , aluminum ,Tired of buying the wrong ones , don't have time left to get a Ph.D. On insert identification,

you need to read the rest of the manufactures naming convention. all "spg422" tells you is the size and shape of the insert, it doesn't tell you anything about the chipbreaker (if the insert has one), the formulation of the carbide, or the formulation of the coatings (if the insert has any).