- Joined

- Sep 4, 2019

- Messages

- 25

Yikes, sorry these photos are so monstrous. This is AFTER I resized them.

Anyway, below is an inexpensive "Router Speed Control" unit sold by Harbor Freight. It says it will work on "any universal AC/DC brush type motor, 15 amps and under." I'm an idiot when it comes to electronics.

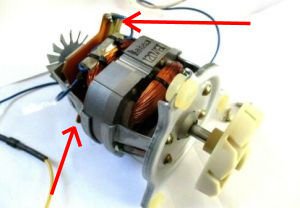

Below are some photos of a little project I am working on for my shop, re-purposing a kitchen juicer to run a buffing wheel. The motor runs at about 8000, which will likely be too fast for my application. Again, excuse my ignorance, but will a speed control unit like that pictured above work on the motor below? Is the motor pictured below a "universal AC/DC brush type motor?" Thanks so much for your help. Appreciate it.

Anyway, below is an inexpensive "Router Speed Control" unit sold by Harbor Freight. It says it will work on "any universal AC/DC brush type motor, 15 amps and under." I'm an idiot when it comes to electronics.

Below are some photos of a little project I am working on for my shop, re-purposing a kitchen juicer to run a buffing wheel. The motor runs at about 8000, which will likely be too fast for my application. Again, excuse my ignorance, but will a speed control unit like that pictured above work on the motor below? Is the motor pictured below a "universal AC/DC brush type motor?" Thanks so much for your help. Appreciate it.

Last edited: