- Joined

- Apr 23, 2018

- Messages

- 6,550

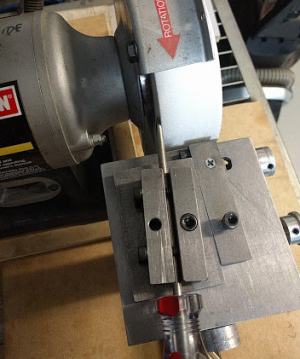

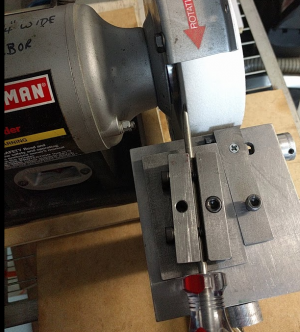

Glad you tamed that wheel. I think your guard has adequate coverage. If you put any more guarding in place, you wouldn't have room left to grind.

Have you had the chance to grind some HSS with that wheel yet? You're in for a treat!

Have you had the chance to grind some HSS with that wheel yet? You're in for a treat!

To be honest I don't like anything spinning at high RPM near my body and sure as heck don't want a piece of rock hitting me in my face if it explodes. However, the conundrum is how do you cover the wheel without impeding access? Even in Harold's design he covers just the top of the wheel, it's open on the sides.

To be honest I don't like anything spinning at high RPM near my body and sure as heck don't want a piece of rock hitting me in my face if it explodes. However, the conundrum is how do you cover the wheel without impeding access? Even in Harold's design he covers just the top of the wheel, it's open on the sides.