- Joined

- Nov 5, 2016

- Messages

- 1,419

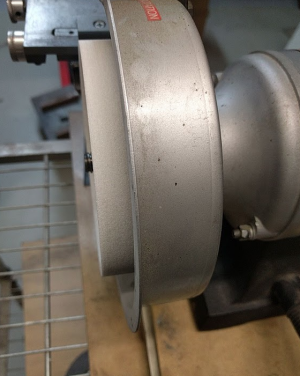

What wheel, brand/size/style/number are you using? If you spin the wheel mounted on the grinder by hand does it look like it's running out?

You said that the adapter you made fits both the grinder's arbor and the wheel without play so that sounds OK. Some people balance their grinding wheels so that is a possible option. If it were me, I would dress the wheel with a diamond dresser using one of your holders on the grinding fixture you made so it is nice and true and see what that does.

Ted

You said that the adapter you made fits both the grinder's arbor and the wheel without play so that sounds OK. Some people balance their grinding wheels so that is a possible option. If it were me, I would dress the wheel with a diamond dresser using one of your holders on the grinding fixture you made so it is nice and true and see what that does.

Ted