- Joined

- Dec 18, 2019

- Messages

- 6,447

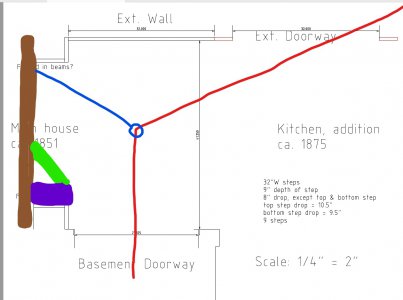

More or less have a plan now, and a pile of assorted lumber. Have material for the ramps, and landing extension. The landing extension will have room to set the whole lathe down at 31" above the floor. This is conveniently within an inch of the lathe stand height. Been waiting for a break in the weather to do the woodwork, as I have to do the large stuff outside. Unfortunately there's a nor'easter right now, but, maybe I can sneak in an hour between downpours.

Have a question about the height of the anchors across the doorways. Is it better to have them down lower, or higher? My buddy says it is better to have them up high near the top of the door. This makes me uneasy, but I can't put my finger on why. I was thinking the anchors should be high enough for the lathe to go under but low enough to step over. Higher would be more convenient, but would require more lumber. Is it stronger or better to go higher in the doorway, up near the head jam?

Have a question about the height of the anchors across the doorways. Is it better to have them down lower, or higher? My buddy says it is better to have them up high near the top of the door. This makes me uneasy, but I can't put my finger on why. I was thinking the anchors should be high enough for the lathe to go under but low enough to step over. Higher would be more convenient, but would require more lumber. Is it stronger or better to go higher in the doorway, up near the head jam?