- Joined

- Aug 29, 2019

- Messages

- 570

If I could drive that far I would drive down to Corpus just to see that lathe. I would love to see it. Thanks for posting this picture.Super! When you started discussing degrees off of level I just wanted to make sure you knew that level to the world didn't have to be the goal. Dead level is probably easier than estimating portions of a bubble off, though.

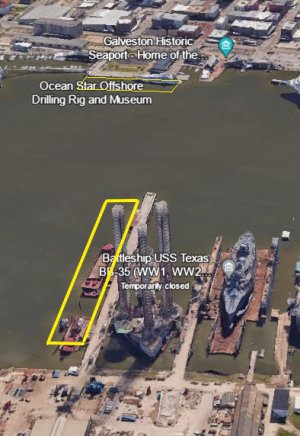

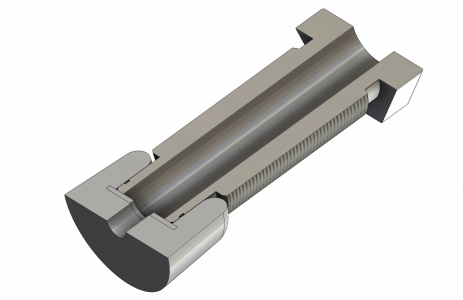

Since ships were mentioned, I found out a couple of days ago that we may have a functional machine shop on the USS Texas again before too long. How cool would that be? Can you imagine machining on this?

View attachment 487911