Do you need isolators or vibration dampening? Is there some sort of performance issue you are hoping to solve?

To bolt or not to bolt is a much debated topic. My lathe is similar, perhaps a little bigger (15x60, light pattern weighs about 2500 pounds). I never bolted it down for the first 25 years, never had a significant problem. I simply used 4x4 plates and shimmed to level. It didn’t cut perfectly straight, but workable. A couple machinist friends insisted that it would never be right until it had been bolted down. So when I built the new shop, I bolted it down (again on plates and shims, it doesn’t live on the jack bolts). It made zero difference. I had avoided lifting the headstock, because the original equipment manufacturer always knows best. Well about 4 years ago, I finally investigated further, there was paint/filler on the V way - cleaned it well, reassembled, much better. I have three other lathes, 4 milling machines, two surface grinders, radial arm drill (50,000 lbs of metal) - plenty of gear, nothing else is bolted. I know plenty of guys that don’t bolt the machines down.

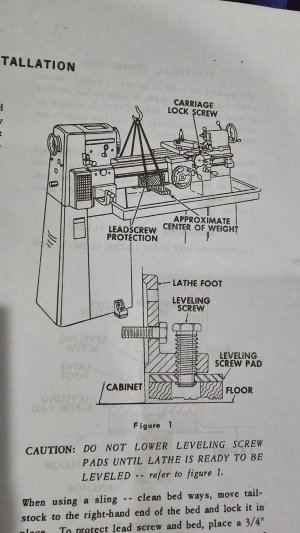

If you are just setting the machine up, try setting it on plates and shim to level (I used the pre-cut stainless “A” or “B” shims). If there is a problem then sort it out (if there is enough vibration that it won’t stay in one place, then you have bigger issues).