-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

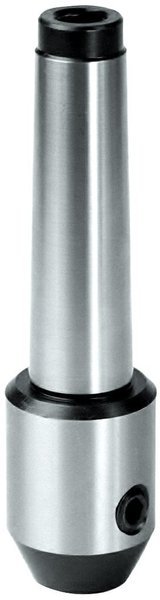

Boring Bar Setup That I Can Use In My Mt#3 And My R8 Mills

- Thread starter motofool33

- Start date

- Joined

- Apr 12, 2015

- Messages

- 1,463

There is. Using a lathe for broaching is very similar to broaching with an E-Head shaper mounted to a bridgeport. Just takes a lot longer and it is all manual. It works fine if you broach infrequently, but it takes a lot of time and effort.Pretty sure there's a tubalcain video on the broaching technique on the lathe.

Bruce

If you are going to broach a lot, there is no substitute to buying a broach set and using an arbor or hydraulic press. Or a shaper!

- Joined

- Apr 12, 2015

- Messages

- 1,463

The MT3 tapers that are in the mill drills have a threaded end for a drawbar

3/8" -16

That is a specialized application and not part of the morse taper standard. Whereas the R8's standard has the drawbar as it's standard.

My point was Morse Taper is designed as a friction lock, with or without a tang...the R8 taper requires a drawbar. The R8 could not physically fit inside a MT3 taper, so it would be very long and does require a drawbar, so changing tools would be tedious.

There's a reason we don't see a MT3 to R8 holder.

- Joined

- Sep 29, 2014

- Messages

- 2,102

You can't push or pull a broach through a blind hole.There is. Using a lathe for broaching is very similar to broaching with an E-Head shaper mounted to a bridgeport. Just takes a lot longer and it is all manual. It works fine if you broach infrequently, but it takes a lot of time and effort.

If you are going to broach a lot, there is no substitute to buying a broach set and using an arbor or hydraulic press. Or a shaper!

- Joined

- Apr 12, 2015

- Messages

- 1,463

You can't push or pull a broach through a blind hole.

The key phase I used was "broach a lot"!

If I was going to do a lot (of blind hole keyway cutting) I would use sinker EDM or a product from this company: http://www.keyseaters.com/index.html

I have had faster results using an end mill to cut the keyway slot and than final shaping with a file than using a lathe with a sharp bit to cut a keyway.

- Joined

- Sep 29, 2014

- Messages

- 2,102

I have had to resort to the lathe once or twice in the past and it is a tedious process at best, a sinker EDM is not a hobbyist friendly process however.

- Joined

- Apr 12, 2015

- Messages

- 1,463

I have had to resort to the lathe once or twice in the past and it is a tedious process at best, a sinker EDM is not a hobbyist friendly process however.

LOL, never said it was...but as a hobbyist and I had "a lot" of blind keyways to do...I would outsource it to a shop that did. There are folks here that might benefit with that knowledge...only reason I threw it out.

Several of my hobby projects grew into products that I market. I certainly don't machine those parts anymore...I've outsourced it due to volume.