E

ecdez

Forum Guest

Register Today

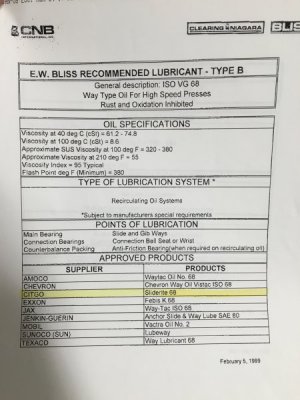

OK, here's another question. I'm all for using 68 oil (especially since I have some already) but how does one get it in the grease fitting? To further confuse matters, the fittings are too big for a normal grease gun so I have no idea what the previous owner was using.

Here's a shot of the fitting for the ways.

And another of the fitting for the crankshaft.

Here's a shot of the fitting for the ways.

And another of the fitting for the crankshaft.