- Joined

- Nov 17, 2012

- Messages

- 48

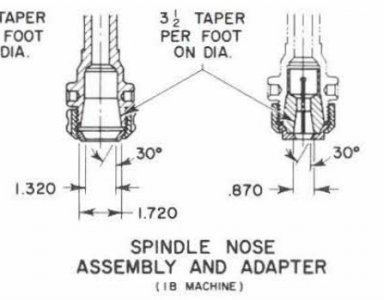

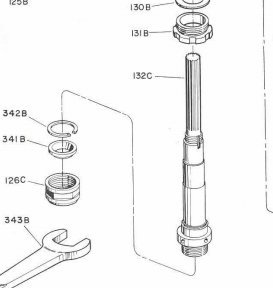

Close inspection of the leading pictures, that does not appear to be stock. The base of the quill should have a 2 1/16" collet retaining nut. There is no drawbar. So what in the world is in that spindle, and what's holding it there?

Good catch @RandyWilson. I found some 1B videos online. None of them look like that. Not sure what that is, but it could be a problem.