-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beginner Hobby Machinist Looking at a Cincinnati Mill. Can anyone tell me about this model?

- Thread starter simspace

- Start date

- Joined

- Jul 20, 2012

- Messages

- 1,238

Looks like a good one to me if it all moves freely. Can clean it up and get it lubricated.

On eBay you can get a power feed that will bolt on for $150 or so

Very similar to a Bridgeport so you can look into Bridgeport videos as far as how to use it.

On eBay you can get a power feed that will bolt on for $150 or so

Very similar to a Bridgeport so you can look into Bridgeport videos as far as how to use it.

- Joined

- Jul 20, 2012

- Messages

- 1,238

By the pictures looks like the current owner may have bought it and never did anything with it or not used in quite a while. No fresh oil and no chips on or around it.

If possible ask to see it run.

If possible ask to see it run.

- Joined

- Aug 29, 2016

- Messages

- 838

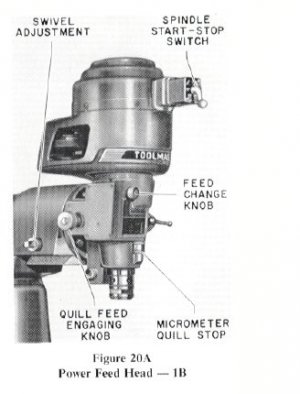

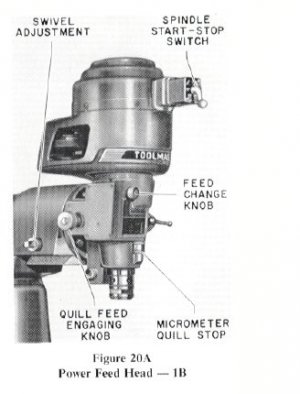

That's a 1B. It does have power feed on the quill.

- Joined

- Aug 29, 2016

- Messages

- 838

I have a 1B. The Cincinnati is twice the machine of a Bridgeport for half the price. It is a very stout piece. It is not a BP clone, no parts will interchange. As mentioned before, the Monoset collets are unique and pricey. I made an adapter for mine to use ER32 collets, so there are options. Fie off any questions you have.

- Joined

- May 27, 2016

- Messages

- 3,469

The first thing I noticed was a milling cutter in a drill chuck. @Jim F advised rookie me that only drill bits go in drill chucks. Blondihacks on YouTube explains why side load on drill chuck says goodbye to any precision.

I am sure the guys here will explain a way to get together the right kit for the quill to mount collet cutters without having to make your way through a precision tooling supplier emporium with your wallet hanging open, offered to all!

I am sure the guys here will explain a way to get together the right kit for the quill to mount collet cutters without having to make your way through a precision tooling supplier emporium with your wallet hanging open, offered to all!

- Joined

- Aug 1, 2019

- Messages

- 337

Get that cleaned up and you should never loose money on it! Enjoy. In over 50 years in the trade, I have never run one of those!

Richard

Richard

- Joined

- Oct 30, 2012

- Messages

- 960

Whoever mentioned the odd ball spindle taper wins the chicken dinner.... that is the major reason these mills go cheap. My .02 do some looking and try to procure the collets (at any price). If you can’t find them well there’s something to seriously consider.

Without those its a an expensive brick.

Without those its a an expensive brick.

- Joined

- Aug 29, 2016

- Messages

- 838

Monoset collets are still out there. Complete sets pop up on eBay all of the time.

HOWEVER!!!

Close inspection of the leading pictures, that does not appear to be stock. The base of the quill should have a 2 1/16" collet retaining nut. There is no drawbar. So what in the world is in that spindle, and what's holding it there?

HOWEVER!!!

Close inspection of the leading pictures, that does not appear to be stock. The base of the quill should have a 2 1/16" collet retaining nut. There is no drawbar. So what in the world is in that spindle, and what's holding it there?

- Joined

- Feb 13, 2018

- Messages

- 179

Good mill at a reasonable price. However, without the proprietary tooling or an adapter, it's just a large doorstop. If buying a bare mill, figure spending 2X - 3X the purchase price for minimum tooling to get up and running. If the mill requires oddball tooling that's even more expensive.

Also, have a plan to move it. If one does not have the towing capacity or the rigging experience to get it on the floor and in position, the sticker shock will be fierce.

jack vines

Also, have a plan to move it. If one does not have the towing capacity or the rigging experience to get it on the floor and in position, the sticker shock will be fierce.

jack vines