-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bearing Ball with Flat for Vise work...?

- Thread starter EmilioG

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

Mikey, I believe the method You describe pretty much is the standard method for squaring stock in the mill, at least its exactly the way I was thought to do it long time ago...

Erik

It's the only method I know of that actually produces a square part. The ball or rod is important to this process. I'm sure you would have said the same thing if I didn't jump ahead in line, Erik. I learned to do this a long time ago, before there was an internet or Youtube, but it's good that they have videos nowadays.

- Joined

- Jul 2, 2014

- Messages

- 7,594

That is a good video, Emilio. Tom is a no nonsense guy. Lays it out there like a master machinist to an apprentice, and I suppose that is what he is actually doing...Here ya go, as requested:

- Joined

- Jul 2, 2014

- Messages

- 7,594

For small parts I often use the pull pins left over from aluminum pop rivets. For larger stuff, un-insulated single strand copper wire or aluminum TIG rod works well. So far, no need for Screwy Balls, but I have the balls and the surface grinder if I want one or more at some point.

- Joined

- Feb 2, 2014

- Messages

- 1,068

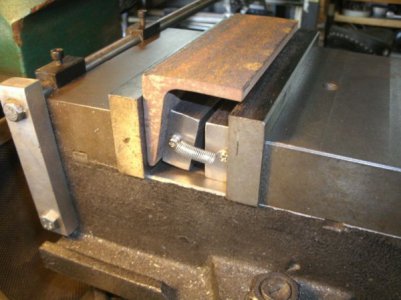

When ever I want to clamp a piece of "C" channel or "I" beam in the vice like this one it never stays solid but just squirts out.

So I tried my hand at making a Quadralel device and as simple as possible.

The springs just hold the whole thing together when setting it up in the vice or when not in use in the drawer.

Used a 1/2" steel ball because that is what I had.

As you can see I raised the angle piece up off the vice base and about 1/8" above the moveable jaws to see how well it was actually held in the vice.

I then tightened the vice like I normally would for a square piece of stock. I was impressed as I struck the stock repeatedly from all different angles with a dead blow hammer and could not measure any movement.

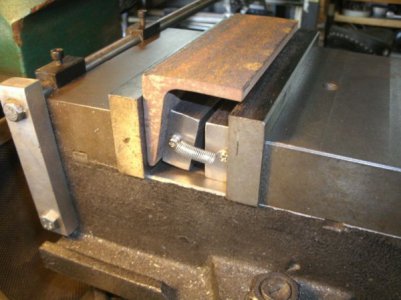

The device worked great for this application but what about for this?

I had to put a block at the far end so that when the vice was tightened the two parts of the Quadralel device don't touch each other. (note gap at front)

It would seem that this setup does not have as much sideways holding ability as the first example but I wouldn't be afraid of doing any milling or drilling operation on the stock.

In my opinion it was well worth the two hours it took to make it and will be quite useful.

Thanks for looking

Ray

So I tried my hand at making a Quadralel device and as simple as possible.

The springs just hold the whole thing together when setting it up in the vice or when not in use in the drawer.

Used a 1/2" steel ball because that is what I had.

As you can see I raised the angle piece up off the vice base and about 1/8" above the moveable jaws to see how well it was actually held in the vice.

I then tightened the vice like I normally would for a square piece of stock. I was impressed as I struck the stock repeatedly from all different angles with a dead blow hammer and could not measure any movement.

The device worked great for this application but what about for this?

I had to put a block at the far end so that when the vice was tightened the two parts of the Quadralel device don't touch each other. (note gap at front)

It would seem that this setup does not have as much sideways holding ability as the first example but I wouldn't be afraid of doing any milling or drilling operation on the stock.

In my opinion it was well worth the two hours it took to make it and will be quite useful.

Thanks for looking

Ray

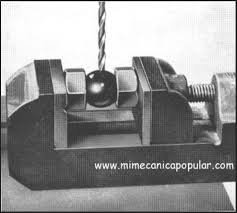

Has anyone tried using the ball bearing with the ground flat on it to hold rough saw stock in a vise?

I just read a machining tip where (it's also in a book), where you take a .750 or 1.00" bearing ball and grind a

flat on it. I've always used a piece of soft aluminum wire. Other's use wood, cylinders of brass, etc...

I'd like to try this. Of course, I would use a piece of brass to protect the flat against the vise jaw.

I don't know if it's what you have in mind, but I've seen a couple variations on this theme:

- Joined

- Jul 2, 2014

- Messages

- 7,594

Many of those "solutions" take up way too much lengthwise space in the vise and are fussy to install at the same time as the part. What we are most often trying to do is compensate for a small amount of out of square or rough condition in the work. We also want to retain as much friction from the vise jaws to the part as possible, that is how vises work. That is why something quick and dirty like a piece of aluminum welding rod or soft copper wire works so well.I don't know if it's what you have in mind, but I've seen a couple variations on this theme:

View attachment 233524