-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel fluting

- Thread starter Earl

- Start date

I took some pictures. The one good fluted barrel I did on my friends Enco mill. I set the cutter in a flute but the picture quality is poor. One of the barrels shows what happens when you dont lock down the knee. That barrel shot ok but it sure looked crappy. I never used it in a match when there were some good gunsmiths thereEarl could post some pictures of your finished results?

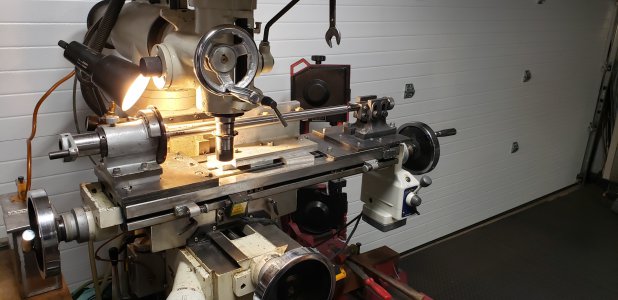

The fluted barrel with the cutter on it turned out to be just over 5 ounces lighter than the one next to it. I actually need only about 4 or 4 1/2 ounces off the barrels to make weight with a Nightforce 15-55 competition scope. I also included some pictures of my setup on the little mill. You can see the extension that I made for the muzzle end of

the barrel.

Are you using a cnc machine or a manual mill? 5 inches a minute equates to 3 minutes per flute. I usually do 6 15 inch flutes, 95-100 thou deep to loose the 5 ounces I need. I don't claim to be fast. It takes me in excess of 2 hours to completely set up, flute, and clean up. At 5 inches per minute, a half hour set up time, and 10 minutes clean up, I would be drinking beer within an hour. When I try to go faster than about 2 inches per minute on the big mill, the cutter jams. I have a couple of brand new 3/16 cutters and some old barrels. I am going to see just how fast I can go with one of them. I will use flood cooling with Rustlick 255. I will let you know how I make out.I go full depth,(.100") in a single pass, but I had a brain fart on the rpm......it is 100 rpm, not 300. 5 inches per minute requires a sharp cutter.

- Joined

- Oct 3, 2015

- Messages

- 985

You are right, Earl......I was confused. I musta been thinking about another job, or that was the number setting on the power feed, or I just had another brain fart....anyways, around 2-3 inches a minute is what my DRO says. My set up is pretty rigid, using hex nuts for an index, and clamping directly to the table.

You cant get much more rigid than that. your using about a 3 1/2 inch cutter with 24 teeth. Mine was a 2 1/2 with 14 teeth. your 100 rpm is close to the same SFM as my "couple hundred" Thanks for the correction. You saved me from burning up one of my new cuttersYou are right, Earl......I was confused. I musta been thinking about another job, or that was the number setting on the power feed, or I just had another brain fart....anyways, around 2-3 inches a minute is what my DRO says. My set up is pretty rigid, using hex nuts for an index, and clamping directly to the table.

View attachment 349949

- Joined

- Oct 3, 2015

- Messages

- 985

Once I have the initial placement of the barrel, I place clamp stops on the back side and on one end. I also use one clamp somewhere in the middle of the barrel that is supported underneath with a copper wedge.

For the the initial set up, I place 2- 5/8 dowels in the T slots and place the straight part of the barrel against them. Clamp both ends, then run the stop clamps on the back side. Then remove the dowels. To index, just loosen the barrel clamps and flip to another flat, pushing it to the stops at 3 points.

What you seen in the pic is a 3/16" cutter, but I normally use a 1/4" on heavy barrels. For a 1/4" cutter x .100 deep, the weight reduction x 6 flutes comes out to .537 oz. per inch. For the 3/16" x .075 deep it's .4 per inch.

For the the initial set up, I place 2- 5/8 dowels in the T slots and place the straight part of the barrel against them. Clamp both ends, then run the stop clamps on the back side. Then remove the dowels. To index, just loosen the barrel clamps and flip to another flat, pushing it to the stops at 3 points.

What you seen in the pic is a 3/16" cutter, but I normally use a 1/4" on heavy barrels. For a 1/4" cutter x .100 deep, the weight reduction x 6 flutes comes out to .537 oz. per inch. For the 3/16" x .075 deep it's .4 per inch.

- Joined

- Apr 29, 2019

- Messages

- 2,066

BUT all this talk about fluting the barrel has me thinking........ and that is always dangerous

While I do not have a heavy contour barrel I thought that I could start with the full .100 deep flute near the chamber end and have it get progressively less deep to where it finally runs out at about 8 - 10 inches from the Muzzle, to avoid getting the barrel to thin anywhere. This is on a Rem 700 SS 7mm Rem Mag with stock 28 inch barrel. It really could stand to loose some weight. at 12.5 lbs it gets heavy a mile back in the woods, and knowing it is a mile back out dragging a deer too. I have also thought of lopping 4-6 inches off the end of the barrel. I really do not need the full 3850 FPS speed.1V1

While I do not have a heavy contour barrel I thought that I could start with the full .100 deep flute near the chamber end and have it get progressively less deep to where it finally runs out at about 8 - 10 inches from the Muzzle, to avoid getting the barrel to thin anywhere. This is on a Rem 700 SS 7mm Rem Mag with stock 28 inch barrel. It really could stand to loose some weight. at 12.5 lbs it gets heavy a mile back in the woods, and knowing it is a mile back out dragging a deer too. I have also thought of lopping 4-6 inches off the end of the barrel. I really do not need the full 3850 FPS speed.1V1

- Joined

- Sep 24, 2020

- Messages

- 1,917

I know it does not help the 12.5 lb, but I use an ice fishing sled to drag deer out.BUT all this talk about fluting the barrel has me thinking........ and that is always dangerous

While I do not have a heavy contour barrel I thought that I could start with the full .100 deep flute near the chamber end and have it get progressively less deep to where it finally runs out at about 8 - 10 inches from the Muzzle, to avoid getting the barrel to thin anywhere. This is on a Rem 700 SS 7mm Rem Mag with stock 28 inch barrel. It really could stand to loose some weight. at 12.5 lbs it gets heavy a mile back in the woods, and knowing it is a mile back out dragging a deer too. I have also thought of lopping 4-6 inches off the end of the barrel. I really do not need the full 3850 FPS speed.1V1

- Joined

- Apr 29, 2019

- Messages

- 2,066

So do I, but no way my gun will be bouncing around in a sled. Gun is always carried, loaded and ready. Never know when it might be needed quick. We do have bear (Usually, not always, in hibernation by deer season), coyote and wolves that all love fresh meat and will follow a blood trail looking for lunch. I never had to shoot a predator in self defense, But I have gotten as close as the gun up, cross hairs settled and safety off staring down a wolf. So far yelling has always worked.I know it does not help the 12.5 lb, but I use an ice fishing sled to drag deer out.

- Joined

- Nov 10, 2013

- Messages

- 376

Earl, thanks for the pics I must have misread I thought you were using a ballnose end mill. That’s a similar set up as mine.