- Joined

- Dec 13, 2012

- Messages

- 466

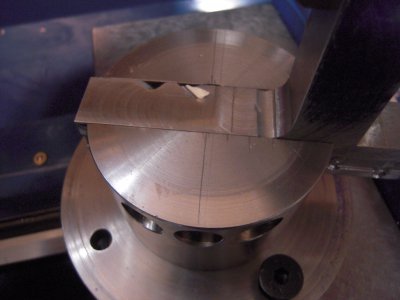

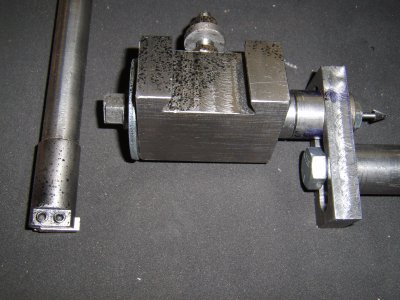

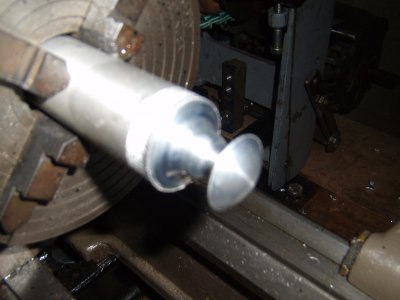

Making a Ball Turning tool post helps if you have a milling machine which not everyone has at this time. I saw a thread, posted in the last couple of months, which showed a Ball turning attachment made from a boring head, mounted in a AXA tool post, using the boring bar attachment. The builder took an inexpensive boring head, attached it to a shaft, inserted it through the boring bar tool post attachment and put a handle on the other end of the shaft. This allowed the boring head to rotate. Once set to the radius of the ball it worked to move the cutting tool.

I thought it was really cleaver and plan to build one for my lathe. He used the same head, mounted on a morris #2 taper in the tailstock as an offset tailstock attachment to turn tapers.

Look around on the forums and you can probably find the post.

This might be the easiest way to get the attachment you want.

HERE is a site where the guy uses a boring head for ball turning.

Gary