- Joined

- Jan 7, 2013

- Messages

- 485

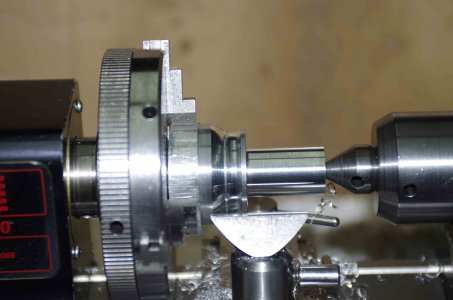

Randy, I think what kd4gif was alluding to was the direction my ball turner was pointing. I placed it that way so a picture could be taken. In actual use, the ball turner is turned and mounted on the back side of QCTH and pointed toward the chuck. It is then centered on the piece being turned. So in use the handle would be on the right side of the tool holder. Hope I have explained it.