- Joined

- Jan 4, 2024

- Messages

- 22

I’m new, both here on the site and to machining in general. I explained in an introductory post I did time in a machine shop 50 years ago but mostly as a gopher and running machines set up by the tradesmen.

A couple of years ago I bought a South Bend 9” C model lathe with the hopes of being able to manufacture small parts for my vintage motorcycles. I was working full time at the time so didn’t have a lot of opportunity to get it right. Now I’m fully retired and trying to get the best out of my lathe.

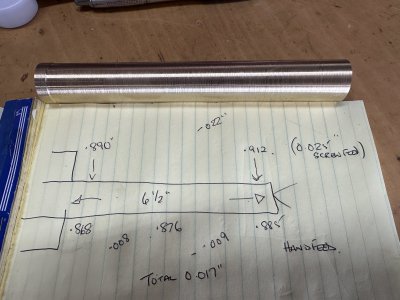

im struggling to get good surface finish and good dimensional stability and repeatability. Ive tried various materials, various tool types, I’ve spent hours making sure tool height are dead nuts on center, I’ve cut dry and with cutting fluid, I’ve taken large depth cuts and shallow too. Still not getting there. I believe the feed rate it too high so today I’m going to change gearing to get it as slow as possible.

I don’t want to be the bad workman blames his tools guy but I’ve thought of maybe buying a new PM lathe and start from a known quantity. I’ve read lots on these forums the debates on new import vs used equipment which always comes with the caution to “make sure you have someone who knows what they’re doing evaluate any used Machines” So it occurred to me my SB may be worn out or seriously out of adjustment. I can run a level over the ways but don’t know what is an acceptable tolerance. Similarly I don’t know anything about spindle wear or carriage wear and backlash. Where do I start? Am I barking up the wrong tree?

Thanks in advance.

A couple of years ago I bought a South Bend 9” C model lathe with the hopes of being able to manufacture small parts for my vintage motorcycles. I was working full time at the time so didn’t have a lot of opportunity to get it right. Now I’m fully retired and trying to get the best out of my lathe.

im struggling to get good surface finish and good dimensional stability and repeatability. Ive tried various materials, various tool types, I’ve spent hours making sure tool height are dead nuts on center, I’ve cut dry and with cutting fluid, I’ve taken large depth cuts and shallow too. Still not getting there. I believe the feed rate it too high so today I’m going to change gearing to get it as slow as possible.

I don’t want to be the bad workman blames his tools guy but I’ve thought of maybe buying a new PM lathe and start from a known quantity. I’ve read lots on these forums the debates on new import vs used equipment which always comes with the caution to “make sure you have someone who knows what they’re doing evaluate any used Machines” So it occurred to me my SB may be worn out or seriously out of adjustment. I can run a level over the ways but don’t know what is an acceptable tolerance. Similarly I don’t know anything about spindle wear or carriage wear and backlash. Where do I start? Am I barking up the wrong tree?

Thanks in advance.