- Joined

- Nov 17, 2017

- Messages

- 56

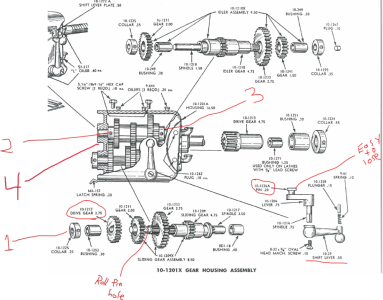

Pick-O-Matic gearbox disassembly.

Start with removal of the lower shaft. Remove collar (1). Gently tap shaft from left to right about an inch. There is a roll pin that goes inside the gear (10-1212). It is not depicted in any official drawings I have ever seen. The hole in the shaft is depicted. Once the roll pin is exposed, drive it out with a small pin punch. Now the shaft will continue out through the gear set. Pay close attention to the shift lever. It has a pin (10-1226A) that can fall off and vanish easily.

Next is the upper shaft. It has two collars (2) & (3). There is a set screw not depicted in the drawing (4) that holds the shaft. Loosen all three and remove the shaft (either way). Note: This shaft has an oil passage and must be installed with the correct orientation for proper lubrication.

Both gear sets will stay together if handled carefully.

With both shafts/gear sets removed you can access the drive gear and the feed gear stub.

And that’s it!

Also, you'll probably find that Pick-O-Matic parts are somewhat rare. So, make a list of what you need/can't find. I'll be glad to loan the ones I have for patterns. Then you can return them when the old Atlas is up and running.

And if you 3D print parts, upload the files to Thingiverse for others to use/access.

Always good to get another Atlas back into operation!

Mike

Start with removal of the lower shaft. Remove collar (1). Gently tap shaft from left to right about an inch. There is a roll pin that goes inside the gear (10-1212). It is not depicted in any official drawings I have ever seen. The hole in the shaft is depicted. Once the roll pin is exposed, drive it out with a small pin punch. Now the shaft will continue out through the gear set. Pay close attention to the shift lever. It has a pin (10-1226A) that can fall off and vanish easily.

Next is the upper shaft. It has two collars (2) & (3). There is a set screw not depicted in the drawing (4) that holds the shaft. Loosen all three and remove the shaft (either way). Note: This shaft has an oil passage and must be installed with the correct orientation for proper lubrication.

Both gear sets will stay together if handled carefully.

With both shafts/gear sets removed you can access the drive gear and the feed gear stub.

And that’s it!

Also, you'll probably find that Pick-O-Matic parts are somewhat rare. So, make a list of what you need/can't find. I'll be glad to loan the ones I have for patterns. Then you can return them when the old Atlas is up and running.

And if you 3D print parts, upload the files to Thingiverse for others to use/access.

Always good to get another Atlas back into operation!

Mike

Attachments

Last edited: