My old belt was really torn up due to extreme misalignment of the countershaft (discussed in another thread). I measured the existing belt and it was .625 wide and .350 deep, and a length of 28 1/4".

The pulley only seems to be about .610 across the top.

The 5L profile is 5/8 across the top and 11/32 (.344) high (

http://www.vbelts4less.com/V-Belt-Specs_ep_45.html) and they also refer to it as a B series on that page.

Yet on another page they list "classic B" (

http://www.vbelts4less.com/Classic-B-Section-V-Belt_c_25.html) as 21/32(.656)

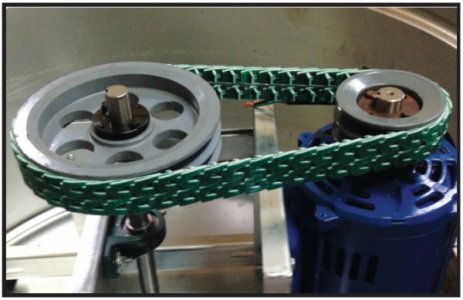

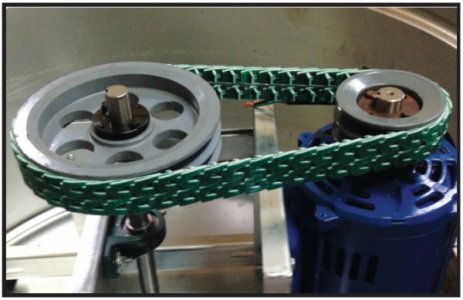

I chickened out on the spindle work and bought a link belt:

Fenner Drives PowerTwist Plus 5/8" B Link V-Belt

- Profile shape: Vee

- Profile size: B/17/5L

- Color: Red

Again, mixing B and 5L. Even though they call it a 5L alternative, it is about .654 across the top, or 21/32 like the B specification. It seems to ride high in the pulleys for my taste. Seems to pull fine so far.

Their chief competitor, Jason Industrial, has this picture in their brochure:

so maybe that's how they're supposed to ride.

There's another factor at play as well. Lathe.co.uk has this quote:

"The drive belt was an unusual size of steel-band reinforced V belt - which has caused some replacement problems in recent years; one solution is to use a "Wedge belt", a deep-sided, heavy-duty version of the standard V belt. "

I went wandering off through Colvin, Machinery's (3 different versions) and the web and now I'm confused even more. The wedge version is too deep. Whichever belt is to be used should be a (belt)X version, as they are cogged like my original and can handle smaller pulley diameters. Machinery 24 lists minimum pulley diameter for B belts as 5.4 inches, and a BX belt as 4 inches. If I look at the pulley dimensions, the top of the pulley measures about .610, which is near the recommended .600 for a 5V series belt, but the 5V series belts are way too deep at 17/32". And the pulley groove is too shallow at .395 or so versus .750 min for the 5V. The B/BX belts call for .730 pulley groove depth so the pulley is way off there as well.

The 5L belt shows a pulley groove depth of .580, which is closer to the .395. The 5L does allow a minimum pulley diameter of 3.5".

I don't understand what the old belt was, unless it was something totally custom. The small countershaft sheave seems to have an included angle of 30 degrees, which is narrower than any of the standards as well.

So, after all that, the 5L280 sure seems to be the only modern equivalent..... And maybe the link belts are OK as well, based on the pictures. Does anyone who has run the link belts on the mill for a while have a comment?