- Joined

- Dec 1, 2021

- Messages

- 151

Hey guys...could use some input/advice on something I am thinking about doing. I've been trying to come up with a good reason or two as to why I shouldn't do this.

So far...no luck. So any input from you guys would help! I'm sure someone has probably tried this in the past but I couldn't find any info on it so far.

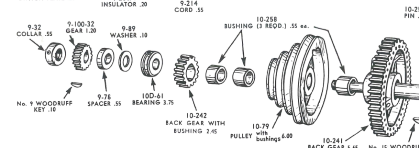

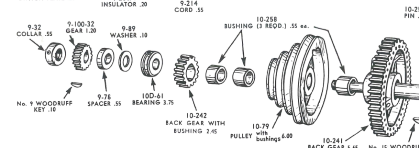

I'm rebuilding the spindle assembly on my A/C 12...new bearings and 3 new bushings. When disassembling I found that the bushing in the spindle back gear (10-242) had excessive wear...that I could wiggle it while it was still on the shaft. The 2 bushings in the pulley (10-79) shown wear but were not a loose fit.

The pulley has the access screw for oiling the 2 bushings...but the bushing for the spindle back gear can only receive whatever oil manages to travel across the spindle from the left roller bearing and from the right from the pulley bushings. Since there was excessive wear on back gear bushing there probably wasn't much oil getting to it.

What I wanted to do was to drill an access hole thru the gear and bushing...use a bottom tap and plug it with a screw like on the pulley.

The small amount of material removed from the gear I'm thinking wouldn't hurt it's integrity and with the screw seated below the bottom land of the gear it wouldn't interfere with the gear mesh. Using the bottom tap I should be able to snug the screw down good enough where it wouldn't walk out. Probably something I would inspect each day before use.

Well...that's my thinking about it. What am I missing here....why would this be a bad idea?

Thanks guys!

Bill

So far...no luck. So any input from you guys would help! I'm sure someone has probably tried this in the past but I couldn't find any info on it so far.

I'm rebuilding the spindle assembly on my A/C 12...new bearings and 3 new bushings. When disassembling I found that the bushing in the spindle back gear (10-242) had excessive wear...that I could wiggle it while it was still on the shaft. The 2 bushings in the pulley (10-79) shown wear but were not a loose fit.

The pulley has the access screw for oiling the 2 bushings...but the bushing for the spindle back gear can only receive whatever oil manages to travel across the spindle from the left roller bearing and from the right from the pulley bushings. Since there was excessive wear on back gear bushing there probably wasn't much oil getting to it.

What I wanted to do was to drill an access hole thru the gear and bushing...use a bottom tap and plug it with a screw like on the pulley.

The small amount of material removed from the gear I'm thinking wouldn't hurt it's integrity and with the screw seated below the bottom land of the gear it wouldn't interfere with the gear mesh. Using the bottom tap I should be able to snug the screw down good enough where it wouldn't walk out. Probably something I would inspect each day before use.

Well...that's my thinking about it. What am I missing here....why would this be a bad idea?

Thanks guys!

Bill

Last edited: