-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are Good Used Lathes Like Unicorns?

- Thread starter MtnBiker

- Start date

- Joined

- May 7, 2020

- Messages

- 263

Picked up the 17x40 on Monday.

This was an informal estate sale and the next door neighbor, Dave, (also a hobby machinist) was selling this machine for the family. Dave brought two friends, two forklifts and had the lathe staged for loading onto my trailer.

Dave fabbed up some supports for the bed to keep the lathe balanced for a safe load. No rigging cost for the win!

Need to mention - my single axle business trailer would have been maxed out (maybe a little over) at about 4,000 lbs. A machinist friend of mine let me borrow his HD two axle. He warned me that this trailer was noisy/clunky with a hydraulic brake (tongue moves back and forth like a U-Haul). So I was expecting some noise going down the road. Sure enough - not disappointed with the clunks.

When I got home I wasn't expecting this:

Unscheduled disassembly of the hub bearings and a lonely wheel (and a few leaf spring members) located somewhere in the high country off I-17. I had no idea this happened. The trailer was stiff enough to keep the springs off the ground...at least the parts that were left. The hardware connecting the axle to the springs was also gone. Yep, the axle was held on by only one side. I will buy some lottery tickets next. When I returned the trailer my machinist friend casually mentioned that "maybe this needed some maintenance". The gift of understatement!

Got the lathe off the trailer and staged for move into garage shop.

Temporary quarters while I clean and inspect. The more grime that comes off, the more I like. Typical machinist, I don't think he ever cleaned the outside - and oil based coolant does leave a mess. But the bits that matter look pretty good.

Ways look good. A lot less wear than a typical late 80's machine I reckon (and I'm sure Arizona's dry climate helps too). The owner was a hobby model maker and cut a lot of brass from the looks of the chip tray. Since I'm not machining the physics packages for our nuclear arsenal I think this should be good enough to get the job done. Note: the orange stuff in the bad is primer, not rust.

Gears for threading look almost new - can't really see any wear. Headstock gears look great as well. All teeth present and accounted for. Everything aligns dead on.

Electrical is pretty immaculate.

Also - what was advertised as a 5 hp turned out be a 7.5 hp dual speed once I got the dust and grime off the motor name plate. 16 speeds on the spindle. The only downside is the price break between a 10hp and 15hp RPC (it's only about $100 more to go to a 20hp so that's likely where we'll land).

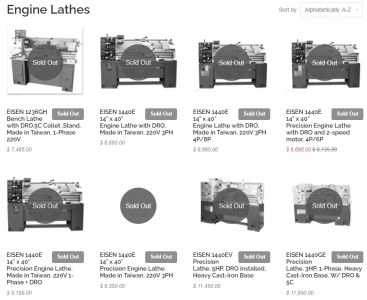

One more thing, in case anyone runs into one of these Shen Jey Taiwan lathes (also sold under the Millport brand) there should be some parts availability as the current Eisen 1640G is nearly a clone. For example, Sterling Machinery just sold out a small batch of OSAMA 1740G new/old stock lathes still on pallets that are even more similar to the the Eisen 1640G. Shen Jey went out of business a few years ago. A lot of parts probably will retrofit just fine.

Will say a little more when I get this thing under power.

This was an informal estate sale and the next door neighbor, Dave, (also a hobby machinist) was selling this machine for the family. Dave brought two friends, two forklifts and had the lathe staged for loading onto my trailer.

Dave fabbed up some supports for the bed to keep the lathe balanced for a safe load. No rigging cost for the win!

Need to mention - my single axle business trailer would have been maxed out (maybe a little over) at about 4,000 lbs. A machinist friend of mine let me borrow his HD two axle. He warned me that this trailer was noisy/clunky with a hydraulic brake (tongue moves back and forth like a U-Haul). So I was expecting some noise going down the road. Sure enough - not disappointed with the clunks.

When I got home I wasn't expecting this:

Unscheduled disassembly of the hub bearings and a lonely wheel (and a few leaf spring members) located somewhere in the high country off I-17. I had no idea this happened. The trailer was stiff enough to keep the springs off the ground...at least the parts that were left. The hardware connecting the axle to the springs was also gone. Yep, the axle was held on by only one side. I will buy some lottery tickets next. When I returned the trailer my machinist friend casually mentioned that "maybe this needed some maintenance". The gift of understatement!

Got the lathe off the trailer and staged for move into garage shop.

Temporary quarters while I clean and inspect. The more grime that comes off, the more I like. Typical machinist, I don't think he ever cleaned the outside - and oil based coolant does leave a mess. But the bits that matter look pretty good.

Ways look good. A lot less wear than a typical late 80's machine I reckon (and I'm sure Arizona's dry climate helps too). The owner was a hobby model maker and cut a lot of brass from the looks of the chip tray. Since I'm not machining the physics packages for our nuclear arsenal I think this should be good enough to get the job done. Note: the orange stuff in the bad is primer, not rust.

Gears for threading look almost new - can't really see any wear. Headstock gears look great as well. All teeth present and accounted for. Everything aligns dead on.

Electrical is pretty immaculate.

Also - what was advertised as a 5 hp turned out be a 7.5 hp dual speed once I got the dust and grime off the motor name plate. 16 speeds on the spindle. The only downside is the price break between a 10hp and 15hp RPC (it's only about $100 more to go to a 20hp so that's likely where we'll land).

One more thing, in case anyone runs into one of these Shen Jey Taiwan lathes (also sold under the Millport brand) there should be some parts availability as the current Eisen 1640G is nearly a clone. For example, Sterling Machinery just sold out a small batch of OSAMA 1740G new/old stock lathes still on pallets that are even more similar to the the Eisen 1640G. Shen Jey went out of business a few years ago. A lot of parts probably will retrofit just fine.

Will say a little more when I get this thing under power.

Last edited:

- Joined

- May 7, 2020

- Messages

- 263

Pretty much all the hobby/home shop sized stuff is sold. My trailer dealer says things are really tight (people starting lawn service/handyman and other ventures). I think a lot of people want to get away from hourly paid and overregulated (restaurants and COVID for instance) industries.This sort of thing seems to be happening a lot lately. I wonder how much is related to COVID and even that stuck ship.

- Joined

- Jun 12, 2014

- Messages

- 4,817

Looks like a very nice find, and definitely a step up in size and capability in line with what you were considering. You could also run it off of a large VFD like the WJ200-110LF or consider a 5 Hp motor with something like the WJ200-075LF. These days it seems the larger 3 phase 5 and 7.5Hp motors are less than there 2-3 Hp counterparts that are inverter rated. The Baldor is a vector type motor, you can run them at much higher speeds if you can go with a smaller pulley. Issue I found with my lathe was the brake was integrated into motor pulley so would be a hassle to switch out since shaft size is different. I have a vector motor for mine, but the stock one does so well off of a VFD I see no reason to change. Of note on the 2 speed motors that are Dahlander motor type (not constant Hp), I had problems tuning the VFD's to them but not the constant Hp.

BALDOR IDVSNM3665T 5HP 1750RPM 60HZ THREE PHASE https://www.ebay.com/itm/353295687286

LINCOLN 5 HP AC ELECTRIC MOTOR 184T FRAME 1760 RPM 3Ø 230/460V AAF4B5T61 https://www.ebay.com/itm/224401192429

MARATHON HP 3 PHASE SEVERE DUTY MOTOR / CATALOG # E473 https://www.ebay.com/itm/272849961686

BALDOR IDVSNM3665T 5HP 1750RPM 60HZ THREE PHASE https://www.ebay.com/itm/353295687286

LINCOLN 5 HP AC ELECTRIC MOTOR 184T FRAME 1760 RPM 3Ø 230/460V AAF4B5T61 https://www.ebay.com/itm/224401192429

MARATHON HP 3 PHASE SEVERE DUTY MOTOR / CATALOG # E473 https://www.ebay.com/itm/272849961686

- Joined

- May 7, 2020

- Messages

- 263

Yep - this one is the not constant Hp type. And band brake is integrated onto the hub for the drive belts.Of note on the 2 speed motors that are Dahlander motor type (not constant Hp), I had problems tuning the VFD's to them but not the constant Hp.

- Joined

- Aug 2, 2020

- Messages

- 563

I went back and forth on a VFD vs RPC myself.

Finally made the decision when a friend got me a 7 1/2 hp motor for the idler for free.

I am very glad I went with the RPC. I can run my ancient lathe, mill and belt sander plus any other old 3 ph piece of junk I drag home in the future.

Finally made the decision when a friend got me a 7 1/2 hp motor for the idler for free.

I am very glad I went with the RPC. I can run my ancient lathe, mill and belt sander plus any other old 3 ph piece of junk I drag home in the future.

- Joined

- May 7, 2020

- Messages

- 263

I see what you did there.Well so what do you think Mtnbiker? Unicorn?

Considering the price, maybe so. Well used. Not abused. In car terms, low mileage for the year and mostly highway. Has had all the service done on time. But it still has 200,000 miles on the odometer. A tear down and quality paint job would make things interesting.

This is an example:

This area of the carriage is a swarf magnet (most of the swarf being yellow metal). Not a museum piece. And the one shot oiler button has been worn down. But...this guy used the one shot oiler a lot. So things still work.

Last edited: