-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone here use a dental drill for removing broken taps and stuff?

- Thread starter Shadowdog500

- Start date

I have drilled out many a tap.especially small ones,with a carbide drill. Run it at about 4000 rpm with NO coolant or oil. The way it works is the carbide gets the hardened steel,or HSS very hot. This removes the temper and the drill scoops it out as it is de tempered.

Exactly what I have used are straight flute carbide drills,or spade tip carbide drills(even better as they don't break as easily). Some years ago,I found a guy selling assortments of 10 small solid carbide end mills,TIN coated nice and gold. They are assorted sizes,and were $10.00 per pack. I wish I'd bought more,as the guy has disappeared. Might have died. These little end mills can drill out broken taps beautifully and I never have broken one.

I haven't been able to find a source for the little 10 packs,but I have seen single ones for sale on Ebay. You might Google around to find them. They have 1/8" shanks,and range from about 1/16" to 1/8",with lots of in between sizes. Exactly what size they are I can't say. They might be metric. I just select the size I need for drilling out the tap. I run them at the top speed in my Bridgeport type mill.

Exactly what I have used are straight flute carbide drills,or spade tip carbide drills(even better as they don't break as easily). Some years ago,I found a guy selling assortments of 10 small solid carbide end mills,TIN coated nice and gold. They are assorted sizes,and were $10.00 per pack. I wish I'd bought more,as the guy has disappeared. Might have died. These little end mills can drill out broken taps beautifully and I never have broken one.

I haven't been able to find a source for the little 10 packs,but I have seen single ones for sale on Ebay. You might Google around to find them. They have 1/8" shanks,and range from about 1/16" to 1/8",with lots of in between sizes. Exactly what size they are I can't say. They might be metric. I just select the size I need for drilling out the tap. I run them at the top speed in my Bridgeport type mill.

I used a 4 flute center cutting 1/8 tin coated carbide em running around 3000 the other day it was in a mill and I used coolant I've never tried it dry ill try that next time I have to do it. But it seems like it needs to be done in position on the bike so those methods may not be possible. If you can reach the head of the screw you can use an old tap ground as a center punch and tap it with a hammer to unscrew it

My dentist gave me some worn carbide and diamond burrs when I asked. They fit a Dremel directly.

Slightly used circuit board type square ended end mills are all over Ebay.

IT WORKS!!!!!

The boxes showed up from China today and I quickly rigged something up to temporarily hook it up. I will make a more permanent setup later.

I lubed it with some mystery oil like ant other air tool.

I ordered 10 small carbide burrs with the drill. I will order some diamond burrs tomorrow to see if they are even better.

I tried it on a bolt and aluminum first and it cut through it like butter. The drill is easy to control, seem to weigh nothing, and stops immediately if it binds(which I like better than a broken bit or ruined part). I kept a light touch and let the but do all of the work.

I tapped a 1/4" piece of aluminum and intentionally broke a rusty old (American made) 10-32 tap in it.

The carbide bit ground the center of the tap out what seemed like about 10-15 minutes (I wasn't timing). Once I drilled the center out the tap lost tension and started to rotate a little. At that point I just unscrewed it with a pair of plier (a tap extractor would have worked well).

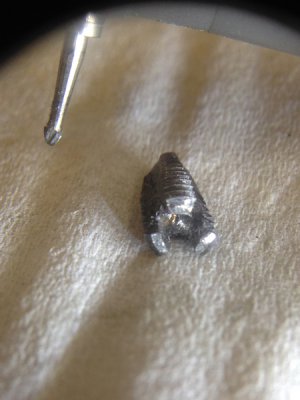

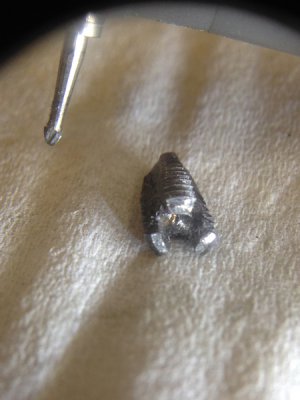

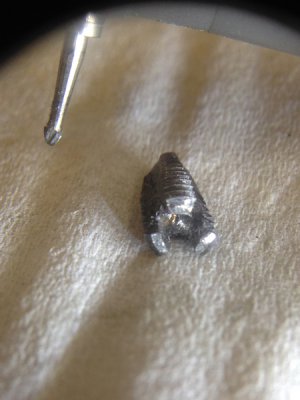

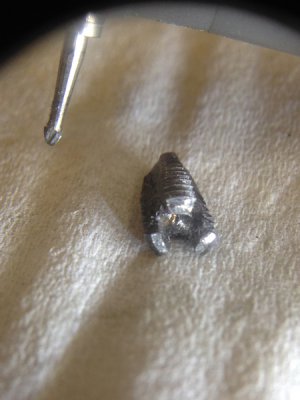

Here are some photos.

Chris

The boxes showed up from China today and I quickly rigged something up to temporarily hook it up. I will make a more permanent setup later.

I lubed it with some mystery oil like ant other air tool.

I ordered 10 small carbide burrs with the drill. I will order some diamond burrs tomorrow to see if they are even better.

I tried it on a bolt and aluminum first and it cut through it like butter. The drill is easy to control, seem to weigh nothing, and stops immediately if it binds(which I like better than a broken bit or ruined part). I kept a light touch and let the but do all of the work.

I tapped a 1/4" piece of aluminum and intentionally broke a rusty old (American made) 10-32 tap in it.

The carbide bit ground the center of the tap out what seemed like about 10-15 minutes (I wasn't timing). Once I drilled the center out the tap lost tension and started to rotate a little. At that point I just unscrewed it with a pair of plier (a tap extractor would have worked well).

Here are some photos.

Chris

Got a link to what you bought? I want one!

John

Drill http://www.ebay.com/itm/111186455016

Hose. http://www.ebay.com/itm/281230283062

carbide bits. http://www.ebay.com/itm/121347175414

you our may want to get diamond bits as well.

i ordered the 4 hose model, they make a 2 hose model as well, but I really don't know what the difference is(other than the number of hoses)

i ordered the ball end carbide bits. They make a bunch of other shapes, wonder if another shape would work even better.

I ran ran it at 30 psi. The book calls for 29-36psi. It had that good dental drill sound at 30 PSI. The air goes in the big white hose which should fit a sports ball air pin perfectly.

Hope this helps.

looking at the bit in the photo, it looks like it is about used up.

Chris

The 2 small holes are for water and air coolant to feed out of the tiny holes near the tip of the drill. The holes near the tip will spray this at the burr while you are using it (remember this is designed to cut bone on live people) The smaller of the 2 big holes is the drive air for the drill, the smaller of the smaller holes right next to the drive air hole is the water coolant connection, the other smaller one is the air coolant connection, and the large hole left over is the return air line.

Look for the drill (we call them "highspeed" in the biz) with a light built in that is air powered, as it spins it generates a light right at the burr. That is a Chinese counterfeit highspeed in the picture that works pretty decent as long as you don't try to rebuild it typically (and it doesn't last as long but at that price its perfect for home use)

You can work up a variable dental footswitch to run it too for not too much moola.

I am working on a coolant mister system using dental equipment, as Chuck stated there is a ton of cool stuff they use and the quality is top shelf.

Look for the drill (we call them "highspeed" in the biz) with a light built in that is air powered, as it spins it generates a light right at the burr. That is a Chinese counterfeit highspeed in the picture that works pretty decent as long as you don't try to rebuild it typically (and it doesn't last as long but at that price its perfect for home use)

You can work up a variable dental footswitch to run it too for not too much moola.

I am working on a coolant mister system using dental equipment, as Chuck stated there is a ton of cool stuff they use and the quality is top shelf.