- Joined

- Jan 4, 2014

- Messages

- 37

Good afternoon, just reporting the activation of another veteran Clausing mill. A fellow antique outboard collector/friend of mine has had this for several years and I always told him if he ever decided to sell it, I wanted to know about it. Always thought it would be the perfect mill to fit my hobby, budget, and workspace. When he called me a few weeks back and said he'd let the Clausing go, it didn't take long to decide to go and retrieve it.

Good afternoon, just reporting the activation of another veteran Clausing mill. A fellow antique outboard collector/friend of mine has had this for several years and I always told him if he ever decided to sell it, I wanted to know about it. Always thought it would be the perfect mill to fit my hobby, budget, and workspace. When he called me a few weeks back and said he'd let the Clausing go, it didn't take long to decide to go and retrieve it.

Other than washing off a healthy layer of grime/protective coating, I didn't do much to it cosmetically. Mechanically, it needed the upper spindle bearing replaced, the fine-feed mechanism needed a gear repaired, and I didn't get a handwheel with the machine (cobbled one up out of brass stock and a handle off an antique Husqvarna sewing machine). For power, I switched the motor over to run on household current instead of 220v until I get around to having a 220v outlet installed down there.

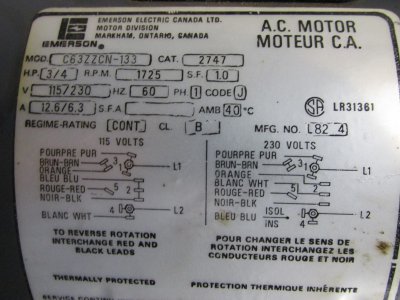

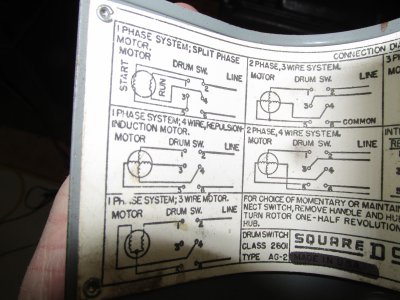

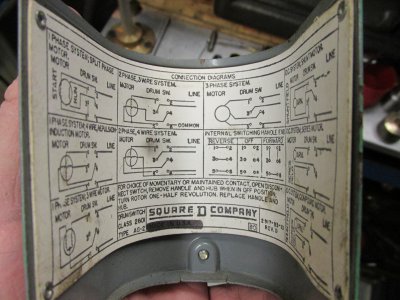

Oh yeah - speaking of wiring, I've run into what seems to be somewhat of a common problem, inasmuch as I can't figure out how to wire this damn thing up to run in reverse. I've looked at wiring diagrams until my eyes were crossed, and nothing quite matches up with the motor I have, which is an Emerson 3/4 hp dual voltage 7-lead thermally protected motor that is reversible. Every diagram I look at lists at least one colour wire that doesn't match what I have, and I hate making assumptions that one can be exchanged for the other.....Just my luck eh. Oh well, I'll get it eventually..... meanwhile, it runs in forward just fine.

As you can see, I'm using the vise off my Atlas shaper until I get a proper milling machine vise... I could have done a better job of clamping the Atlas if I'd taken the base off. One thing I can see with this mill is I'll be limited to a vise of 12-13 inches or less overall length, otherwise I have difficulty seeing/using the dial on the y-axis handle.

Best,

T2

Last edited: